Qual é o desafio da indústria de petróleo, gás e petroquímica?

A indústria de petróleo, gás e petroquímica é um setor altamente competitivo e com muitos ativos. No processo de produção de petróleo e gás, existem poucos desafios que irão coagir a indústria a mudar sua forma de trabalhar:

Aging facilities and legacy systems

Atualizar instalações e sistemas complexos que exigem monitoramento e manutenção contínuos custa muita mão de obra e recursos financeiros.

Hazardous environments

Da produção e transporte ao refino e processamento, essas operações ocorrem em ambientes perigosos e exigem produtos confiáveis para garantir segurança e eficiência.

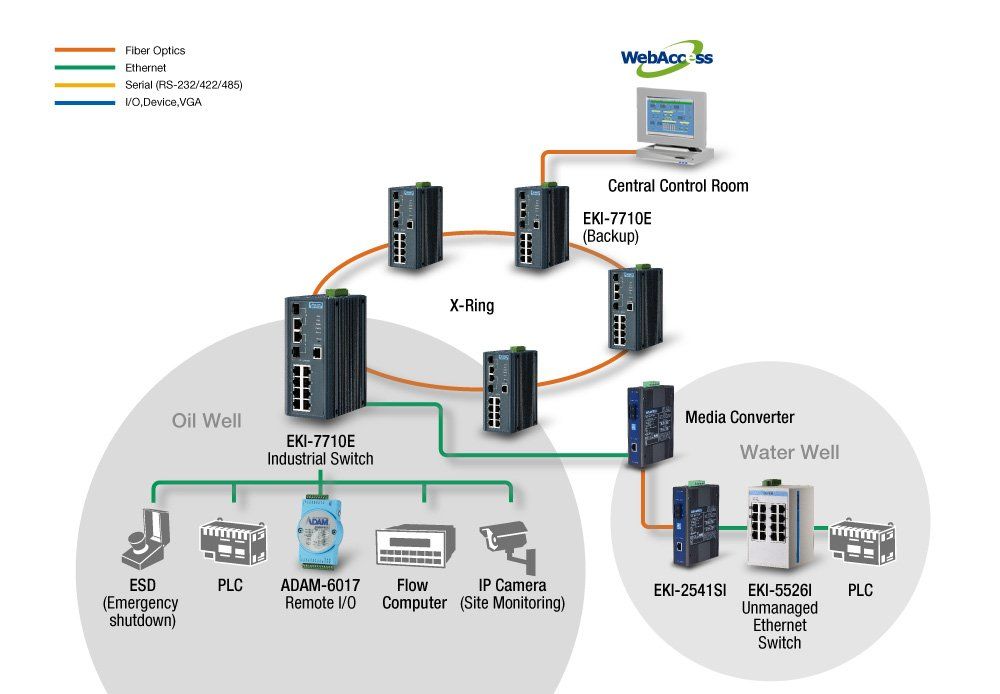

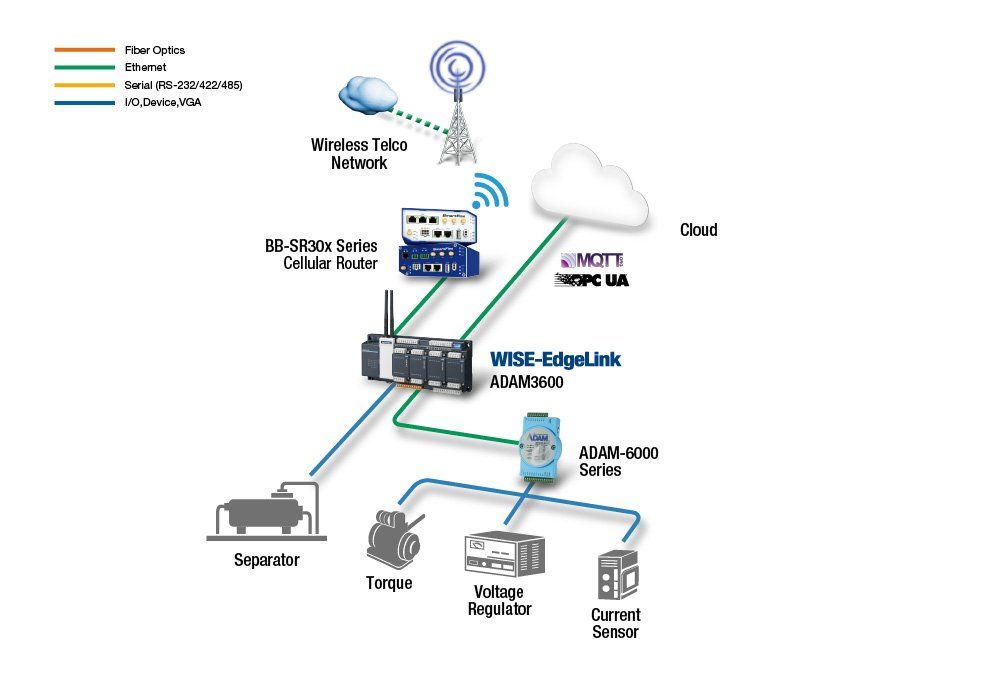

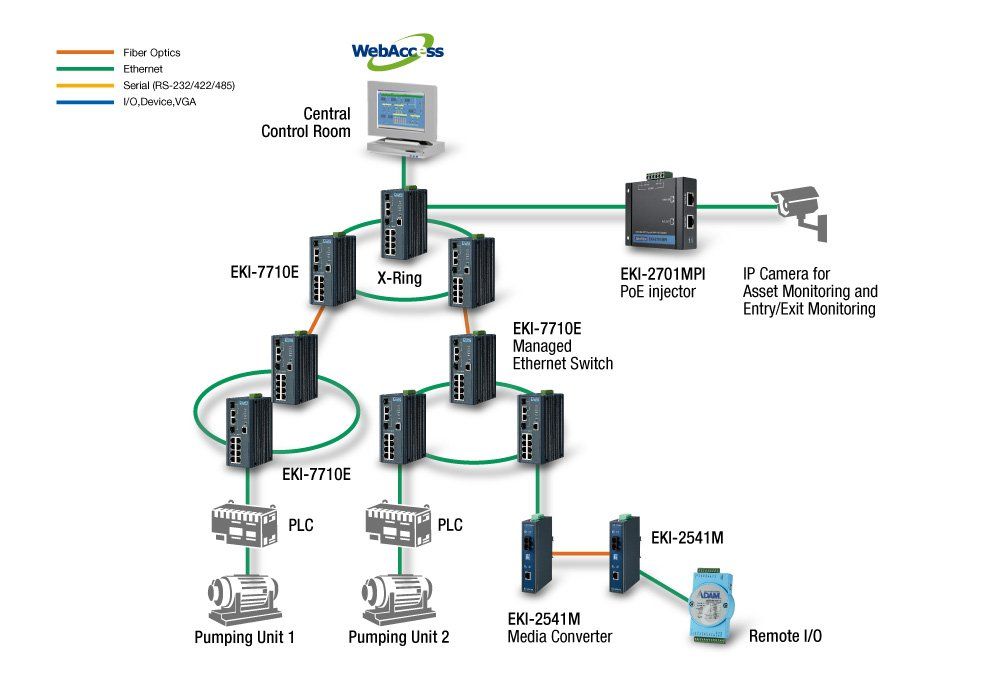

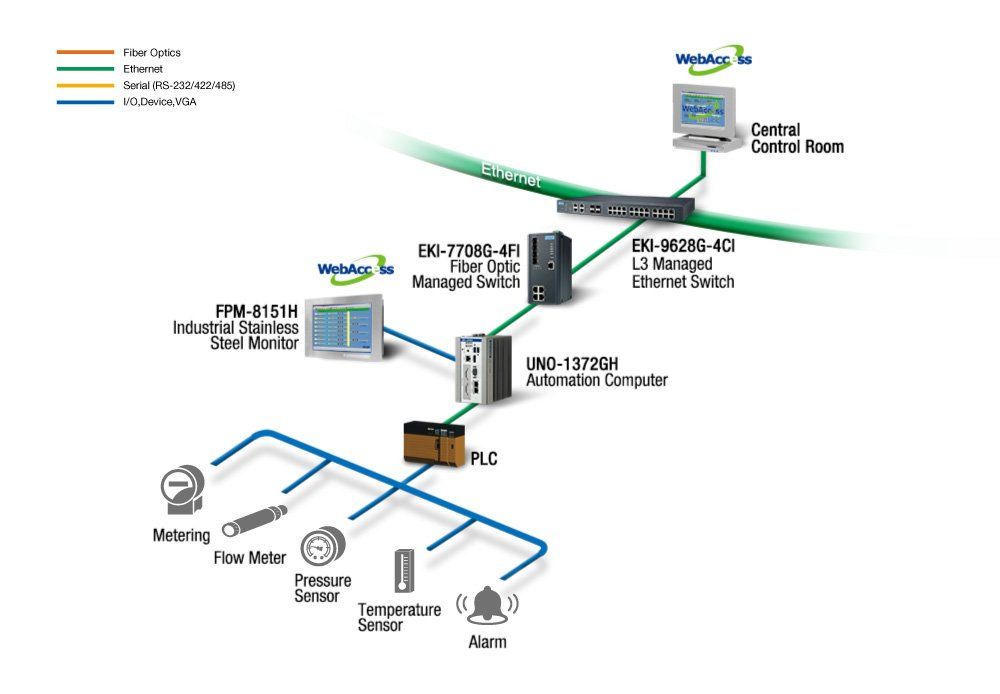

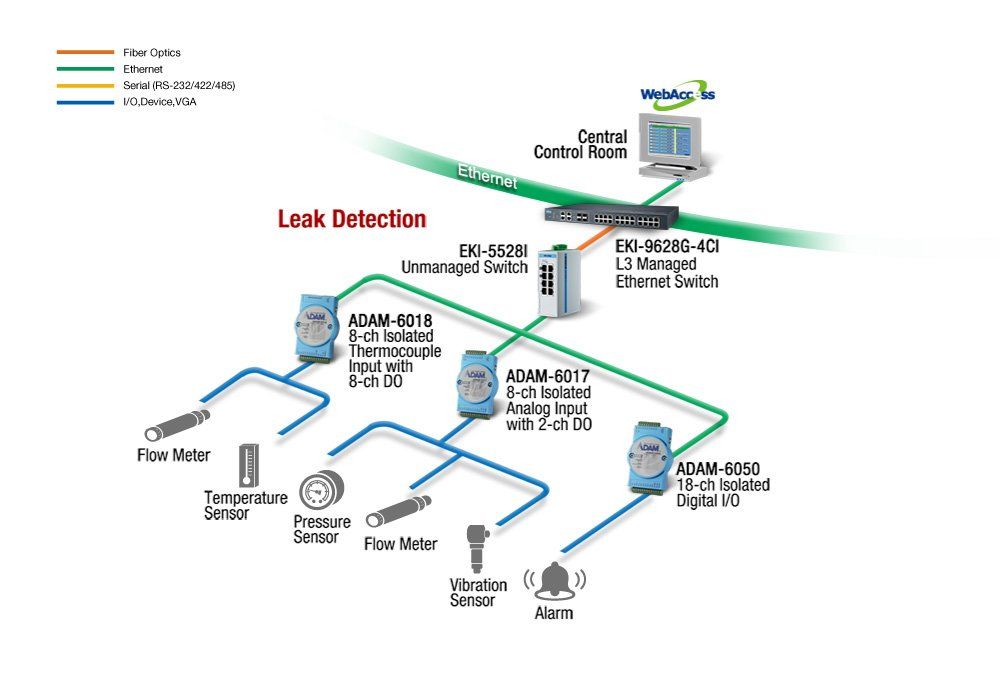

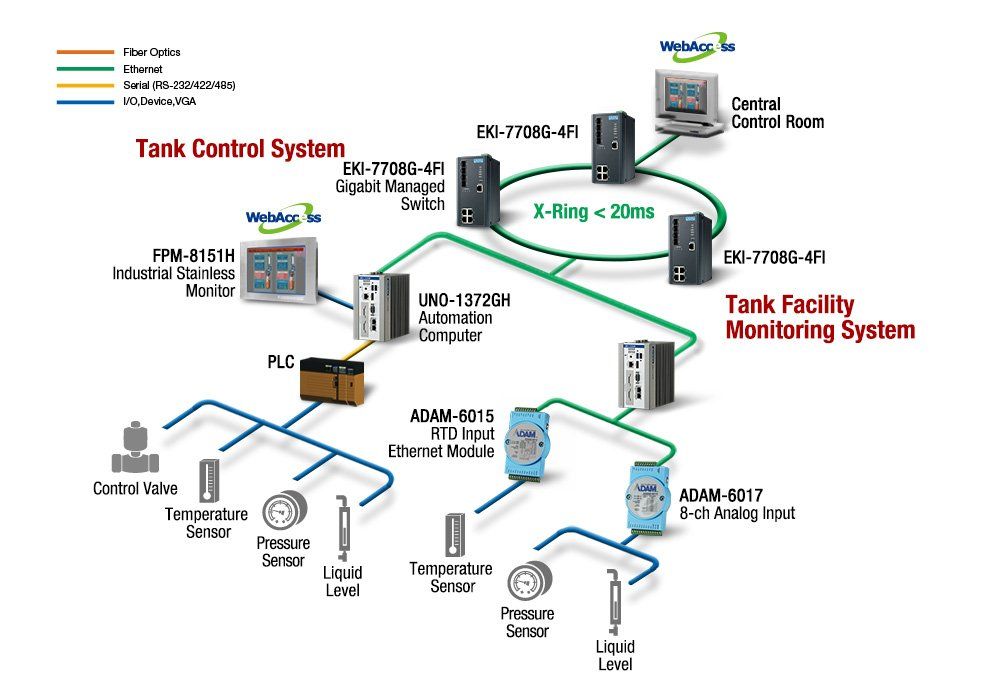

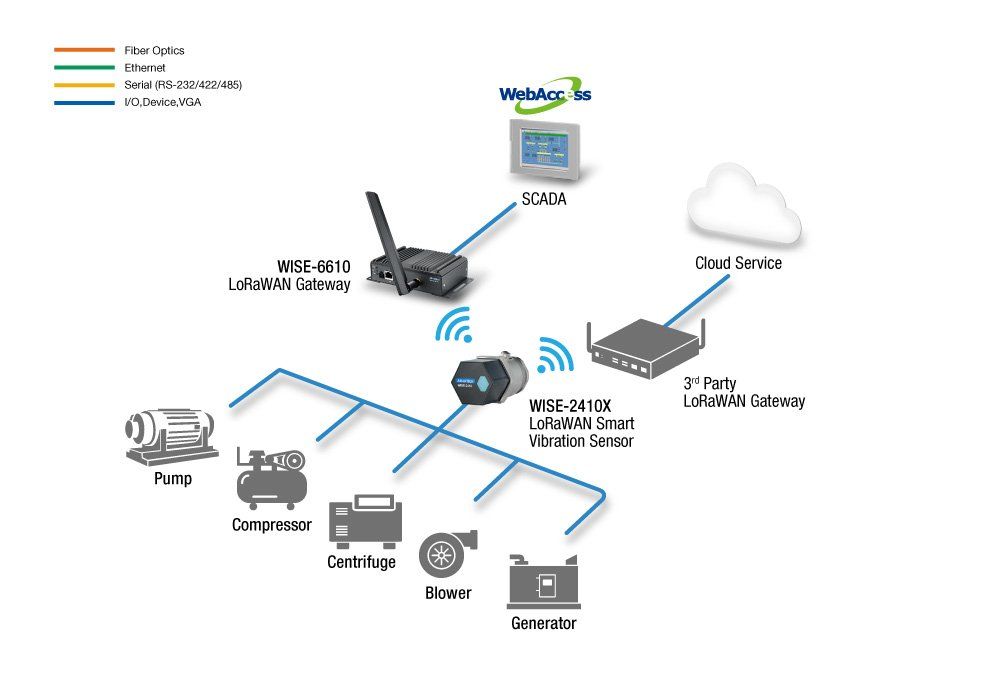

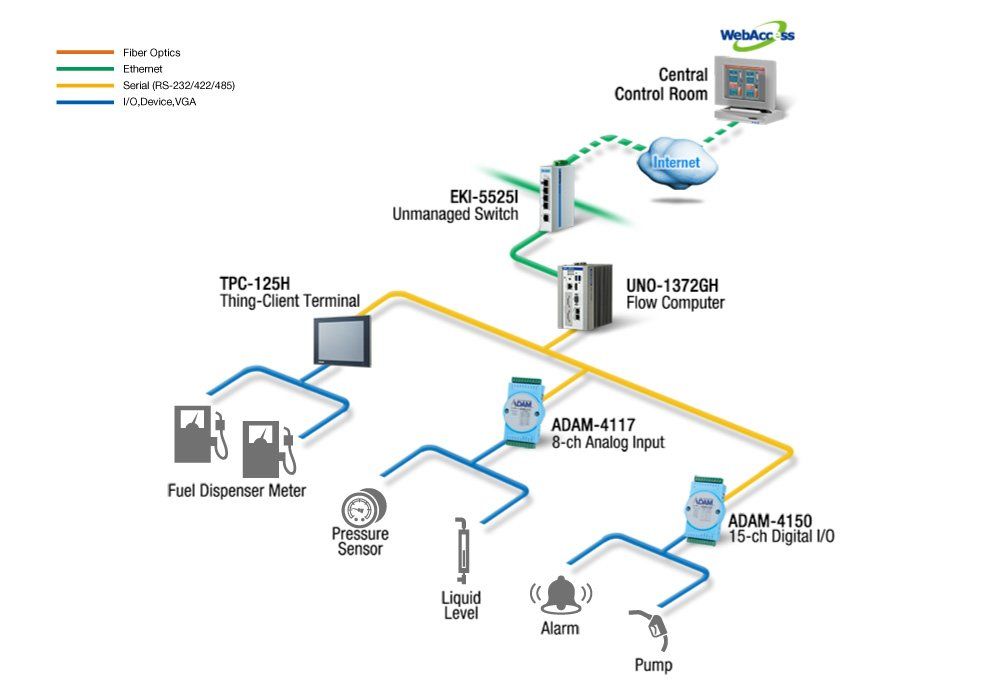

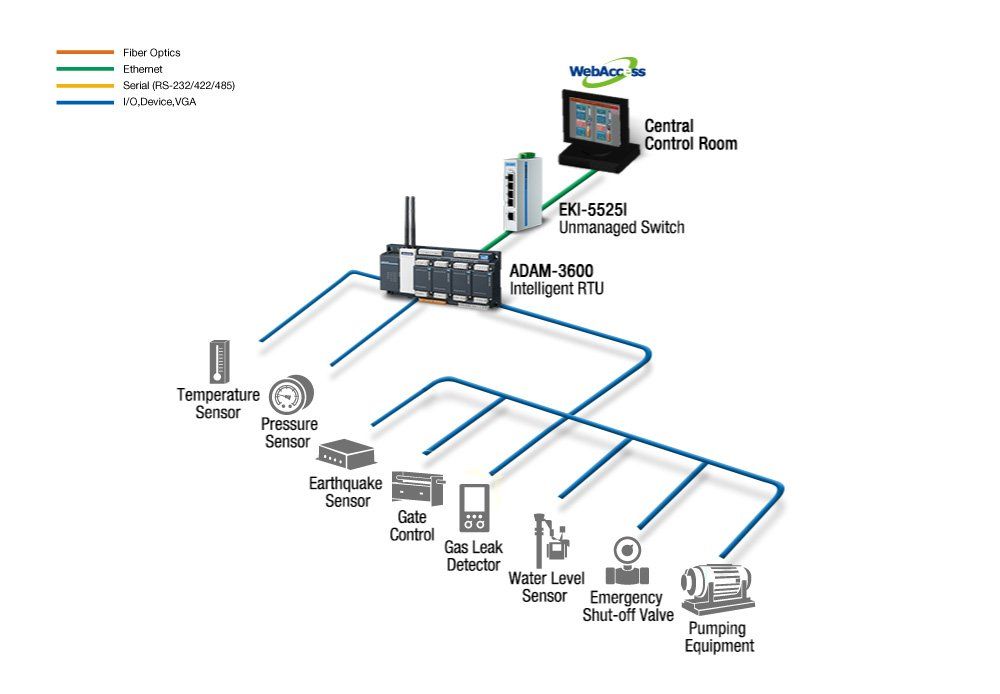

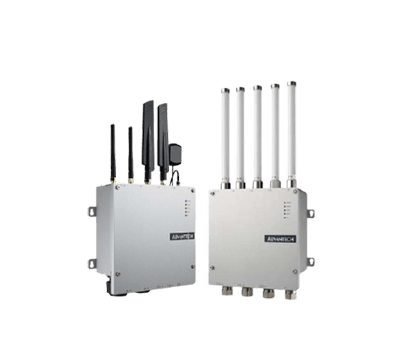

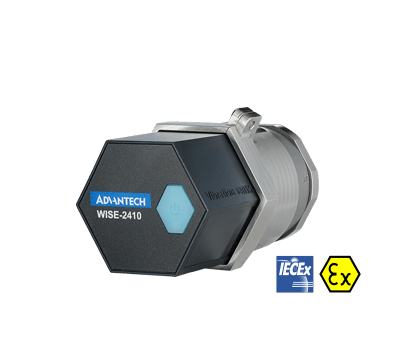

Soluções IIoT confiáveis para monitoramento remoto

Aproveitando mais de 40 anos de experiência na indústria de automação, a Advantech projetou diferentes soluções para a indústria de petróleo, gás e petroquímica para monitorar e antecipar possíveis falhas de equipamentos em tempo real para evitar o tempo de inatividade do equipamento e minimizar os custos operacionais.

Manutenção de Equipamento

Remote diagnostics and maintenance providing advanced warnings of equipment problems