Remote Facility Management Solutions for

Facilities Operations and Maintenance

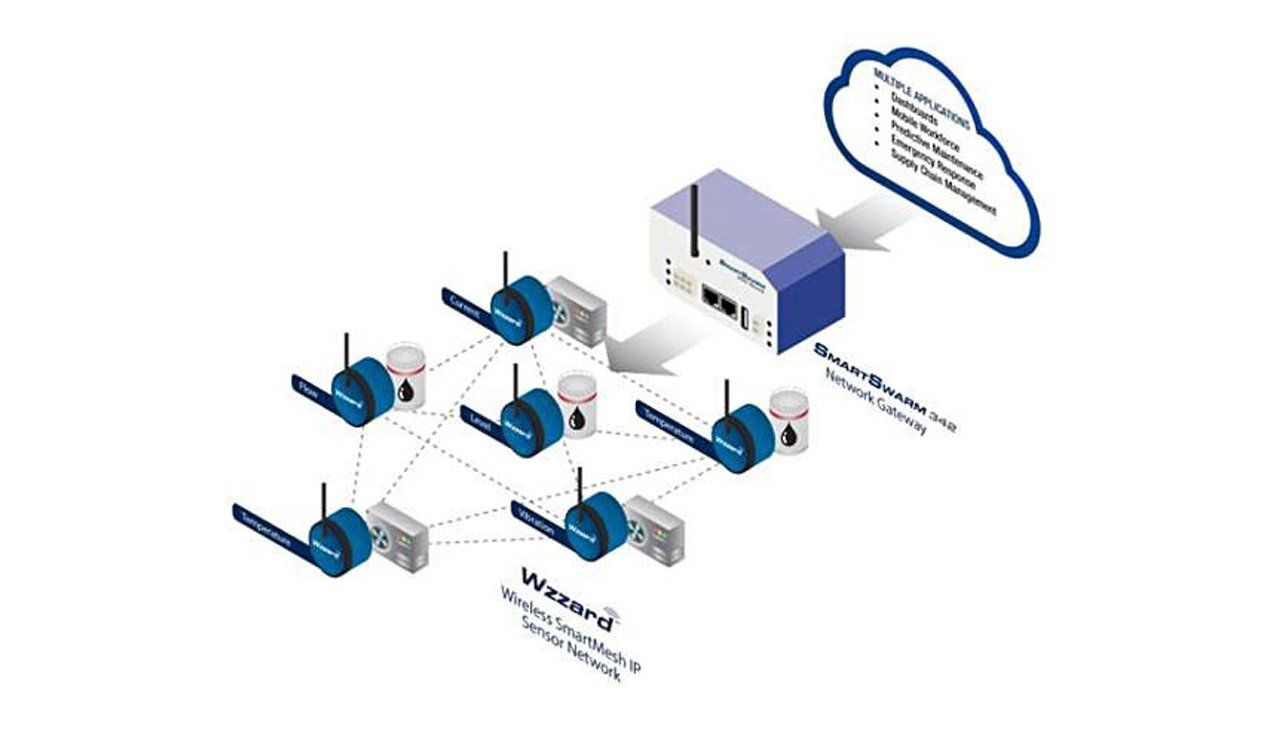

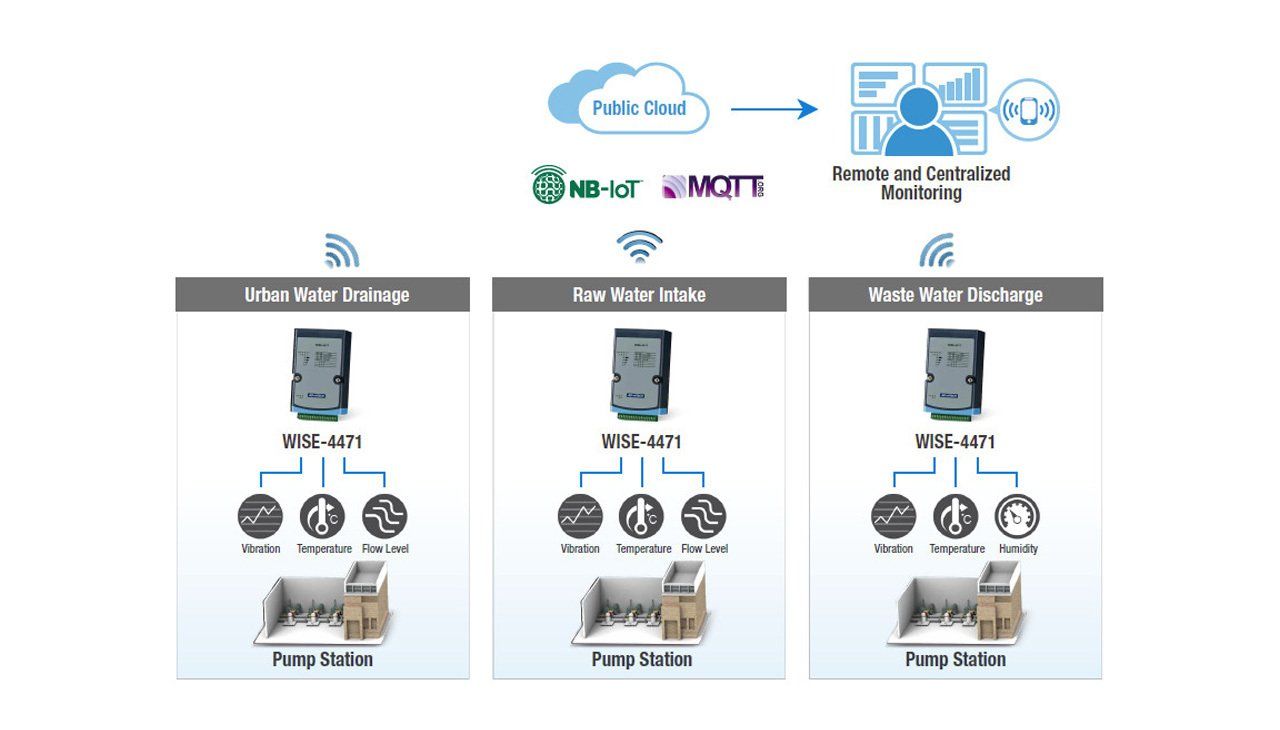

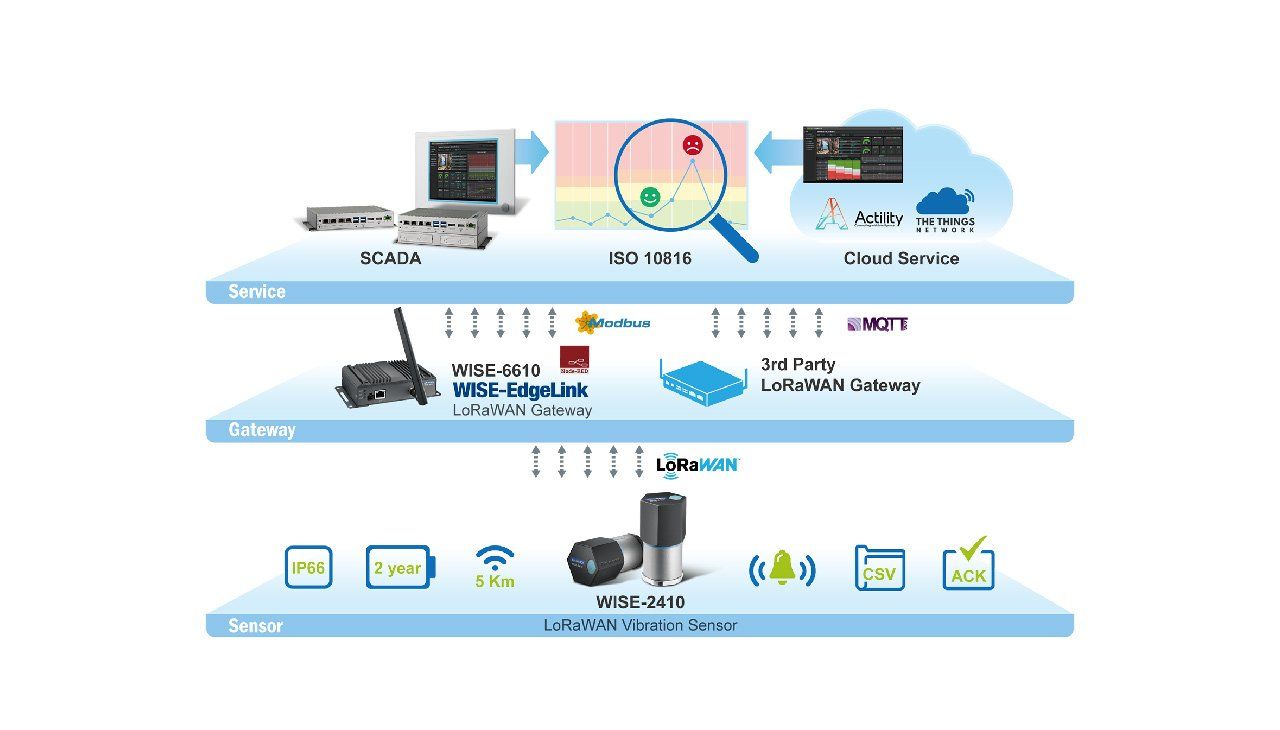

Industries such as manufacturing, energy, data centers, and infrastructure often face challenges in collecting accurate, real-time data from geographically dispersed equipment. Without reliable connectivity and intelligent integration, it becomes difficult to monitor remote assets, analyze performance trends, or implement predictive maintenance strategies that sustain uptime and operational stability.

At Advantech, we deliver remote facility management solutions designed to meet diverse industrial requirements, integrating hardware, software, and cloud platforms to ensure seamless visibility and control across sites. Our solution framework covers:

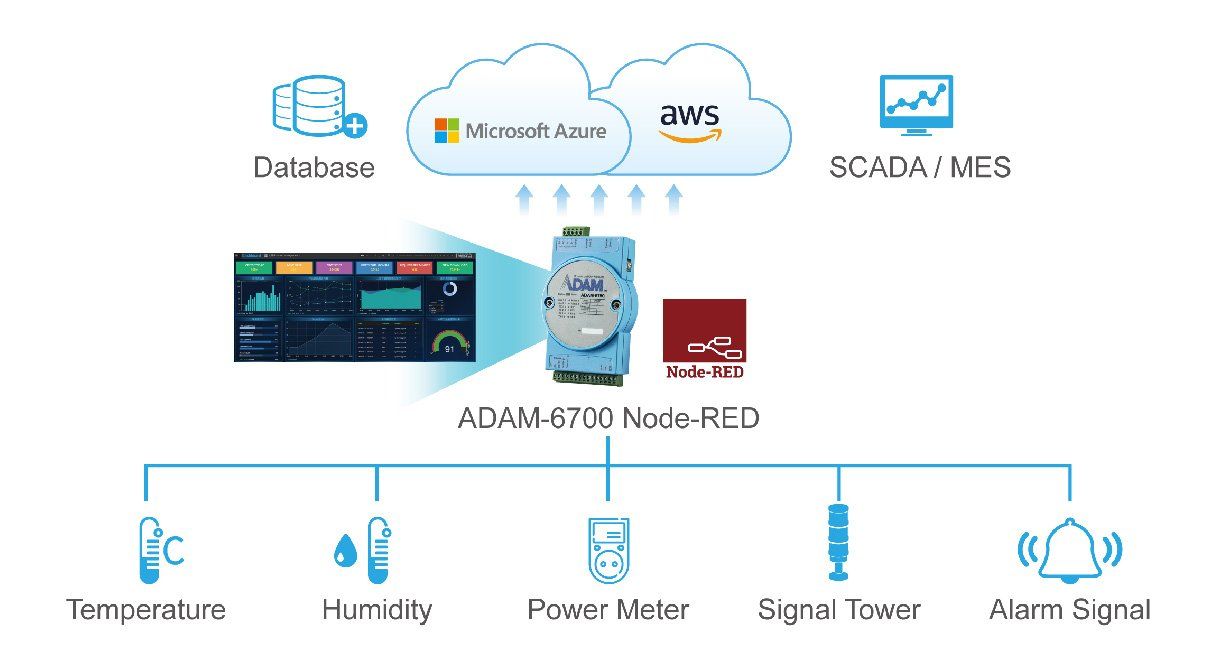

• Data acquisition (DAQ) – precise and stable signal collection from sensors and machines

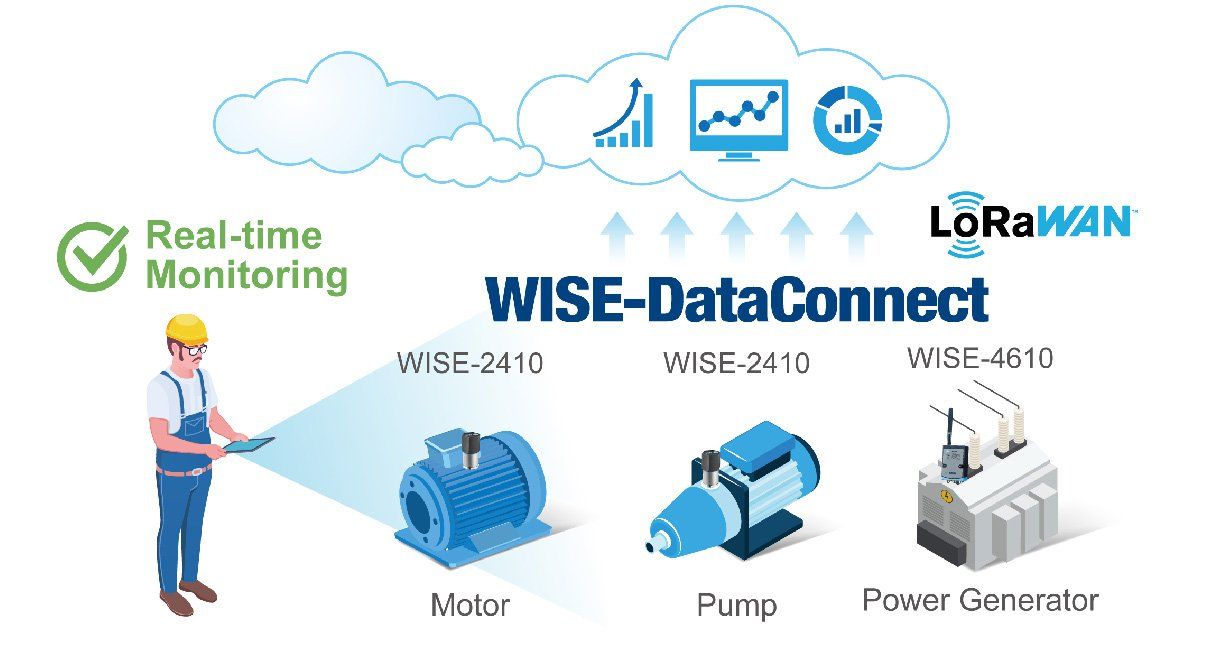

• Condition monitoring – early detection and prevention of equipment health issues

• Device management – centralized configuration and supervision of distributed assets

• Equipment inspections – automated checks, alarms, and operational status reporting

• Facilities operations and maintenance –

streamlined workflows connecting field devices to the cloud

Through these end-to-end solutions, organizations can enhance operational efficiency, boost productivity, and strengthen facility management with secure, scalable, and intelligent remote access.

Industrial Remote Facility Management Product Features

Industrial Remote Facility Management Solutions

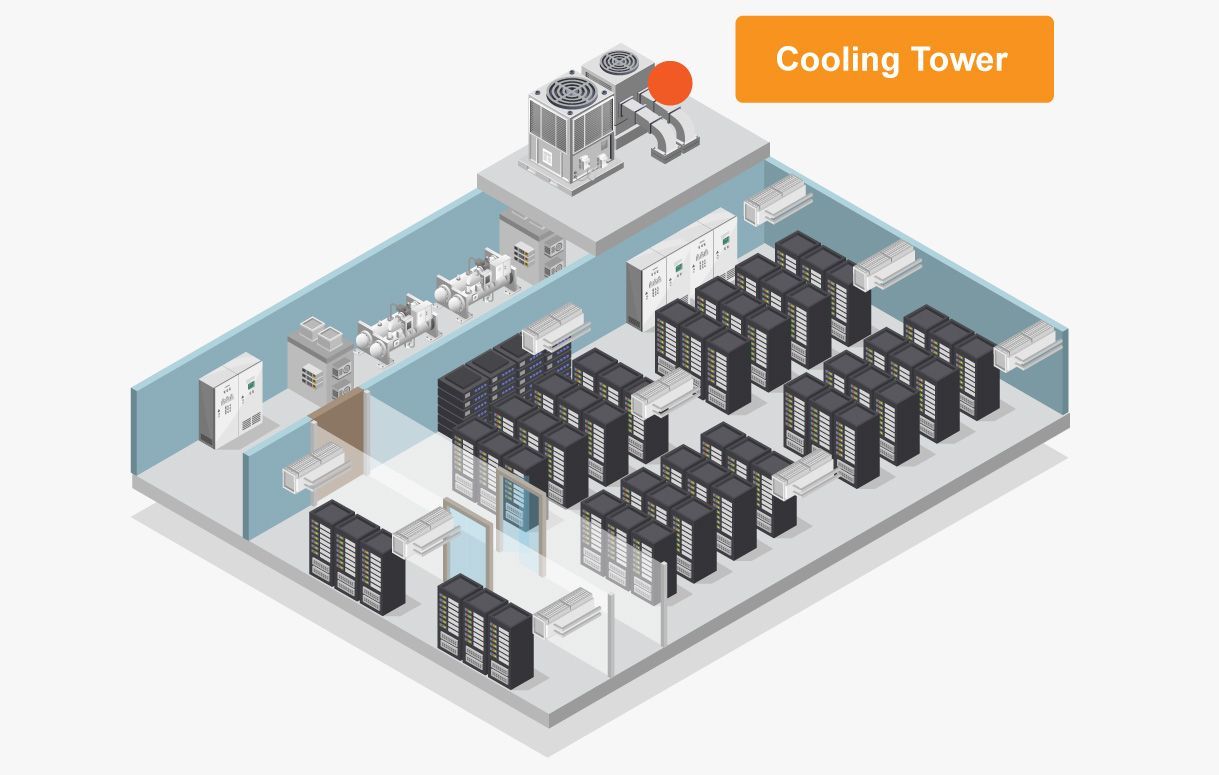

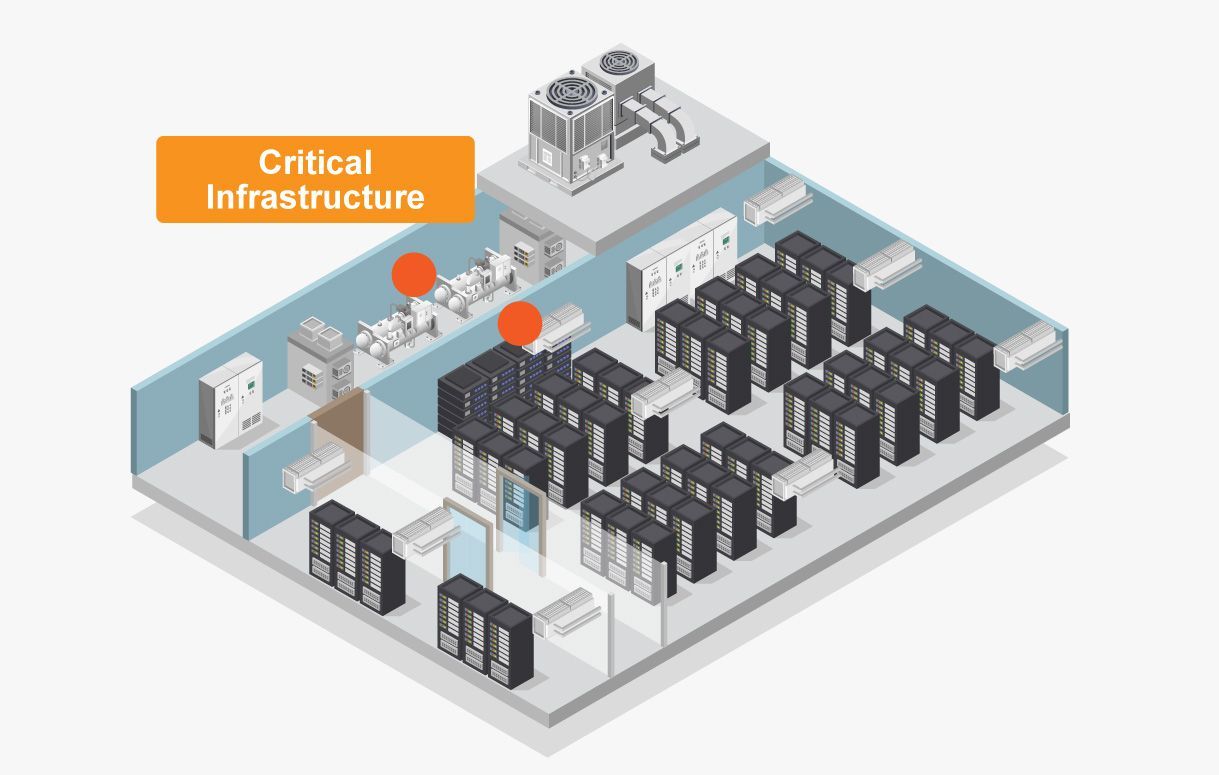

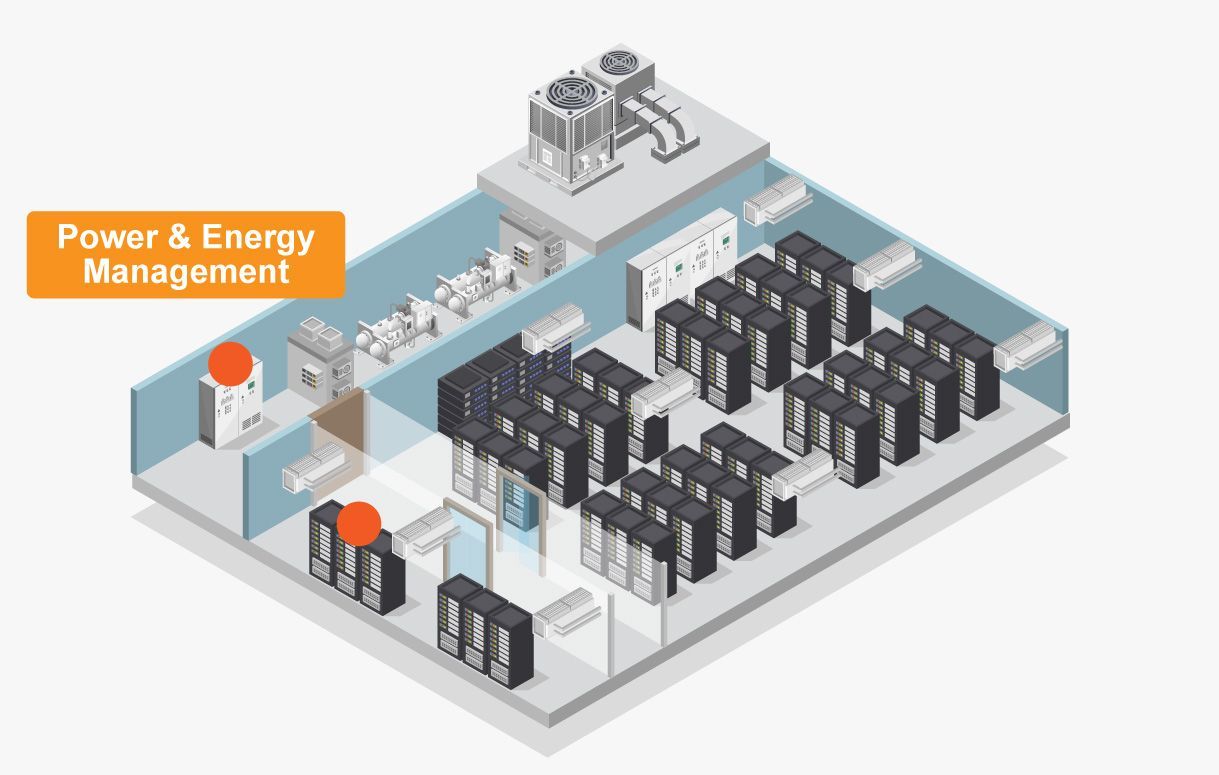

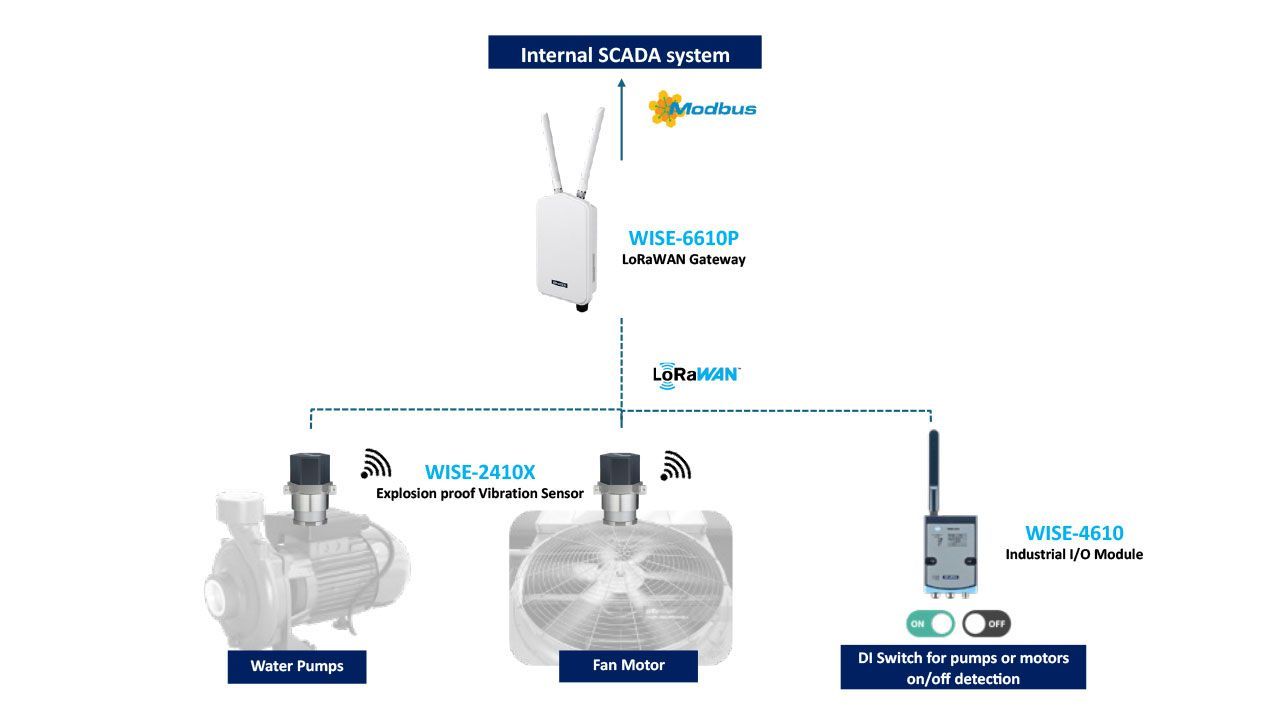

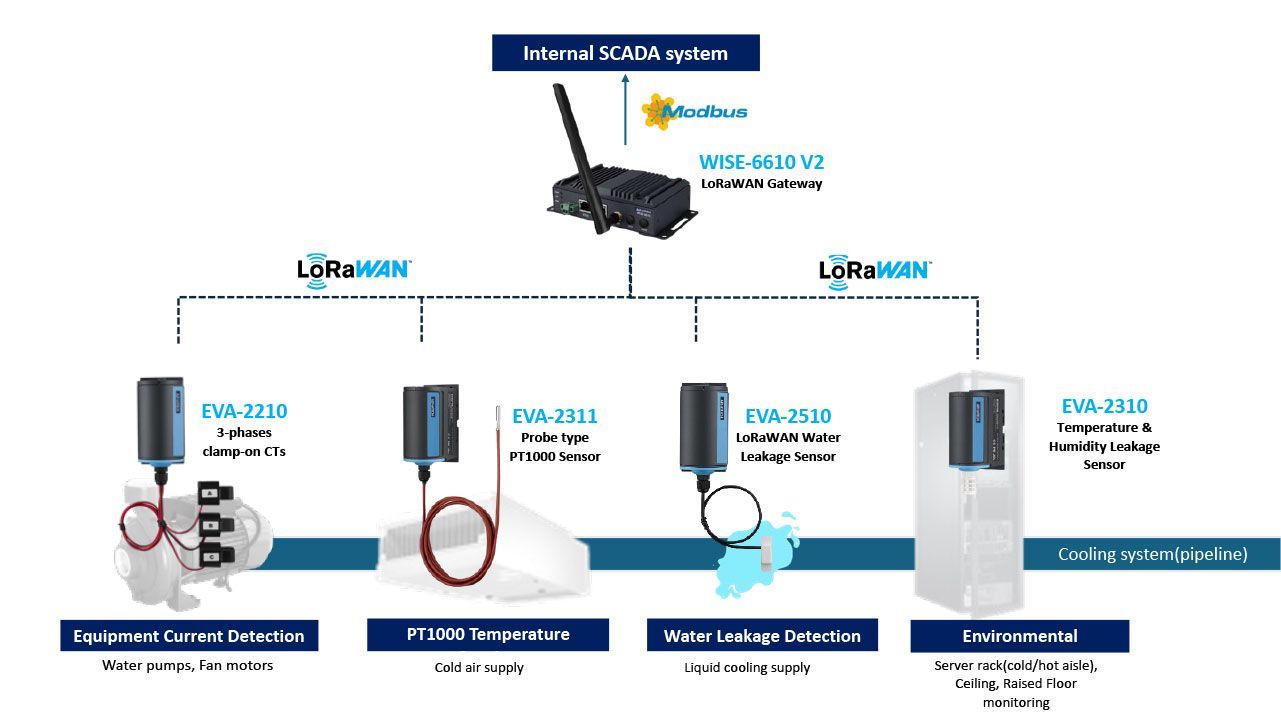

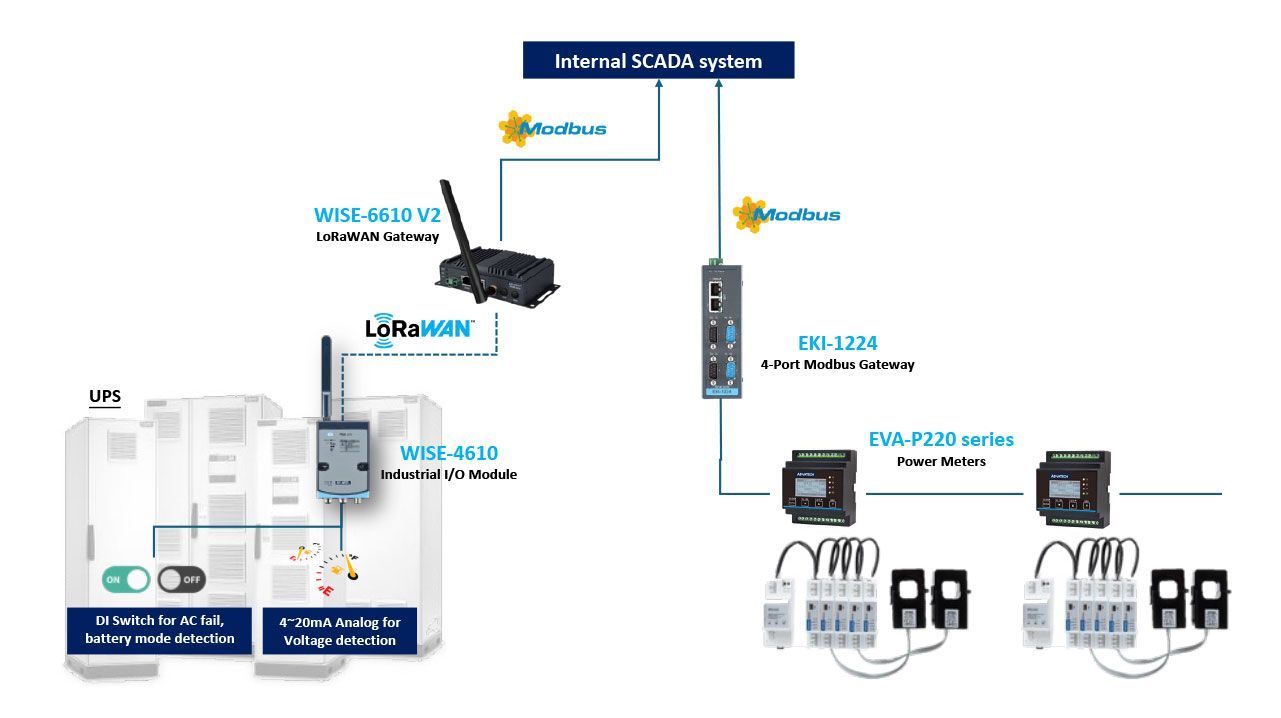

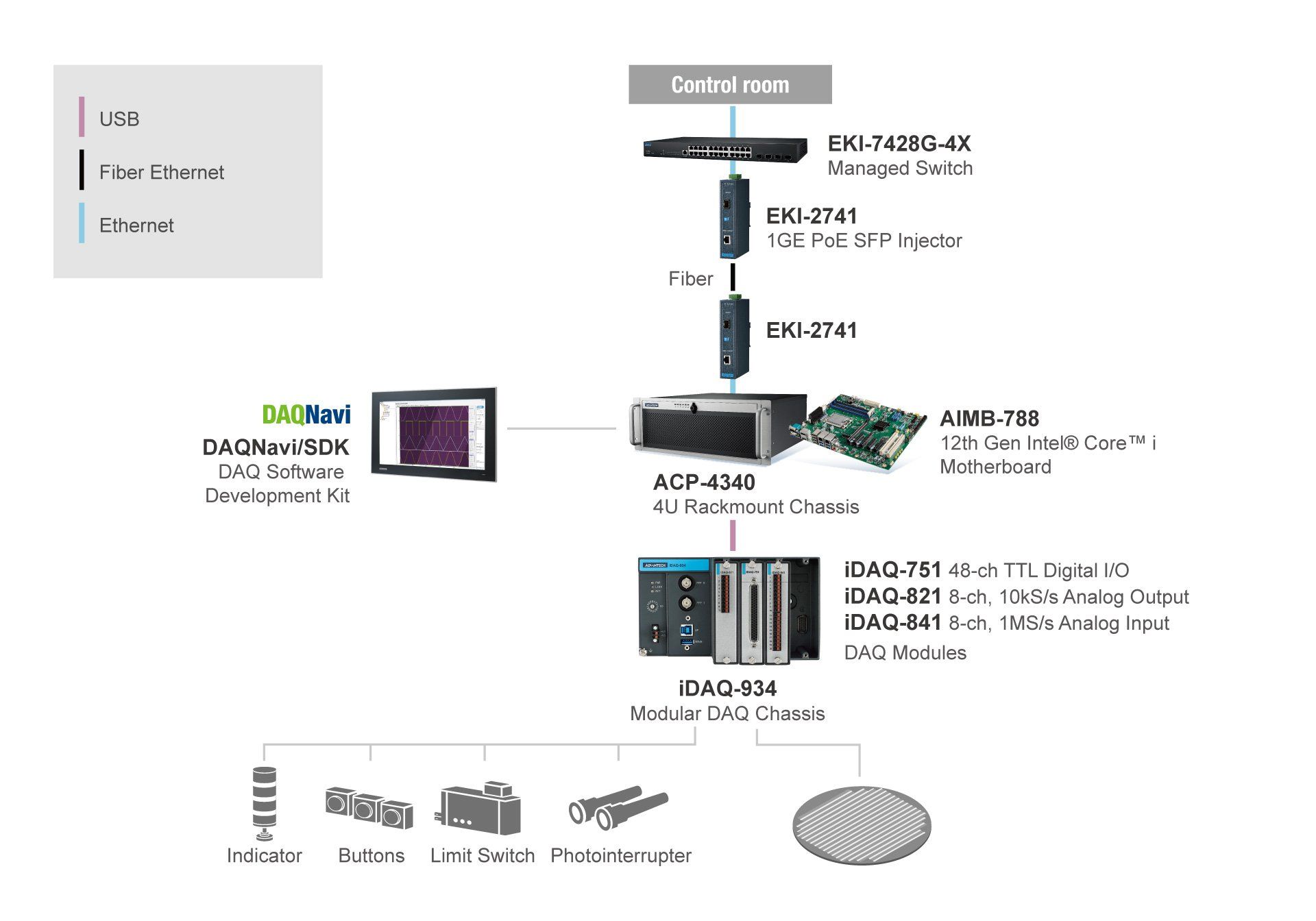

Data Center Infrastructure Management

Smart Monitoring for Real-Time Visibility and Control

Application Scenario

Success Stories & System Topologies

Products Offerings

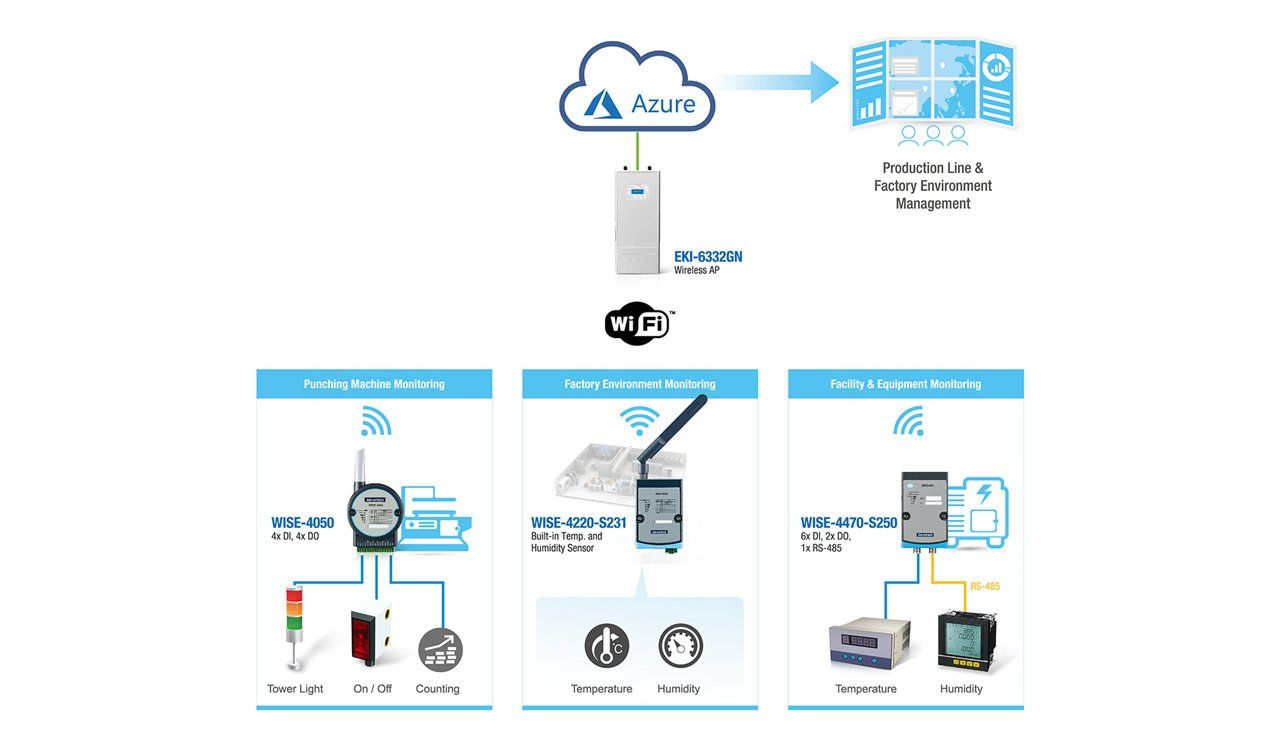

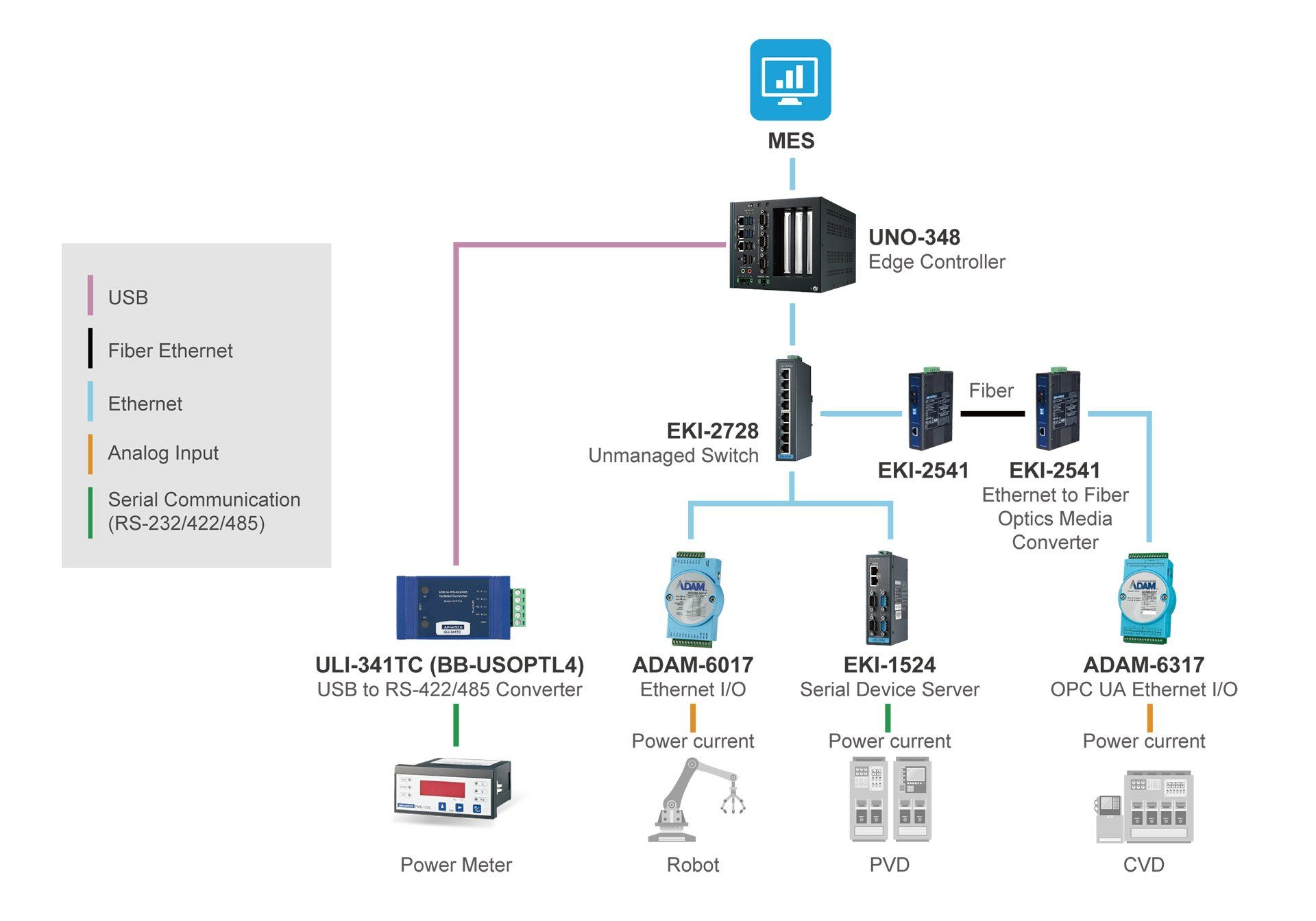

Factory Remote Facility Management

Realizing Factory Intelligence

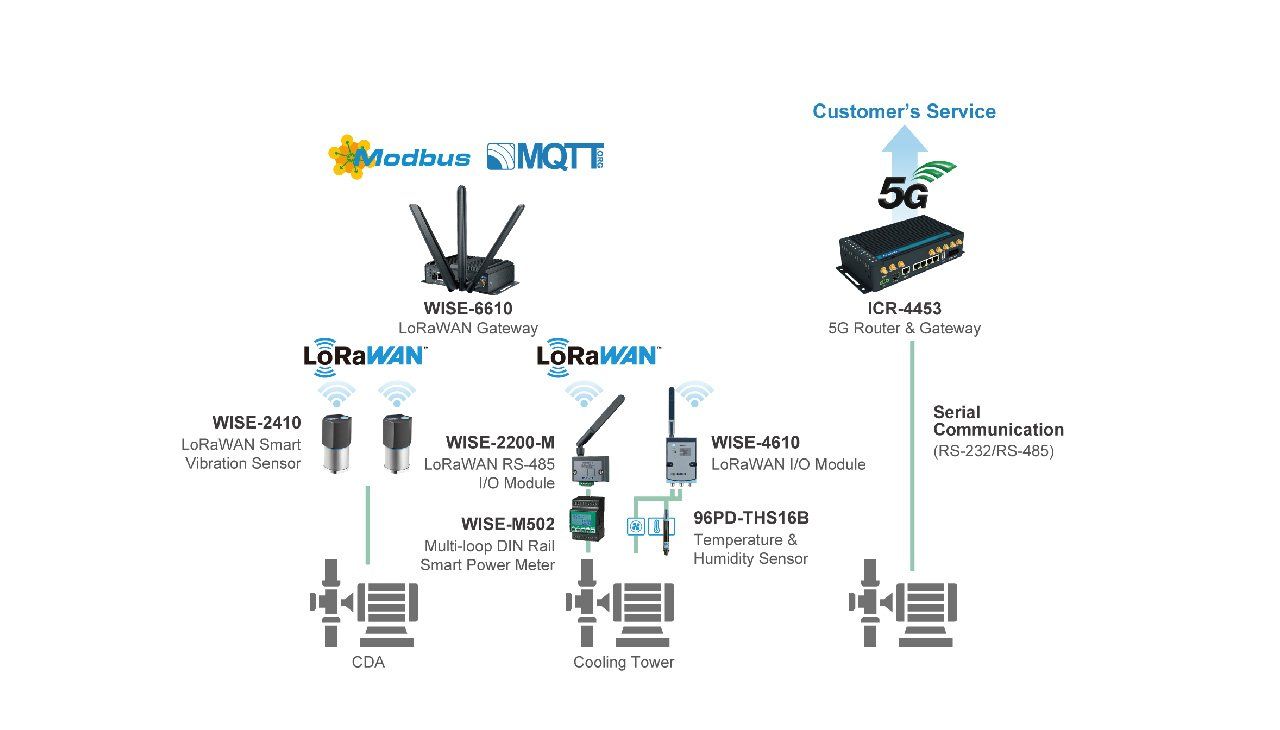

Application Scenario

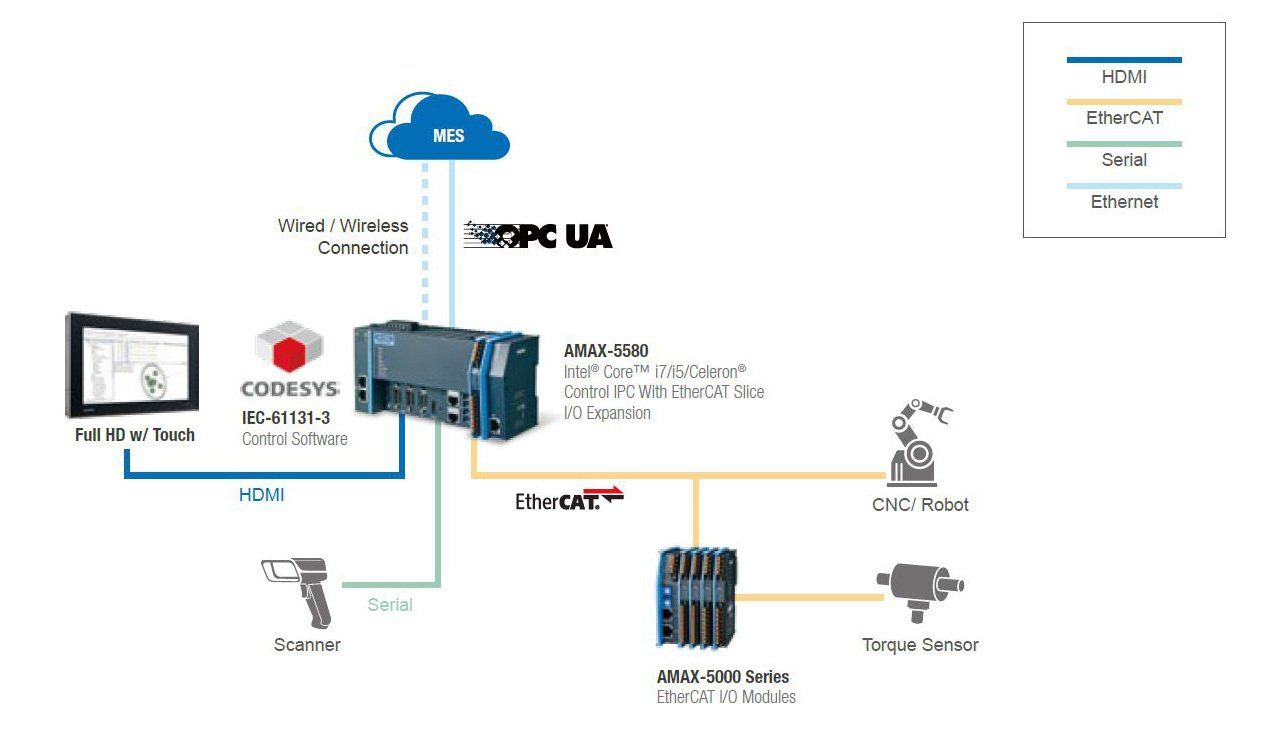

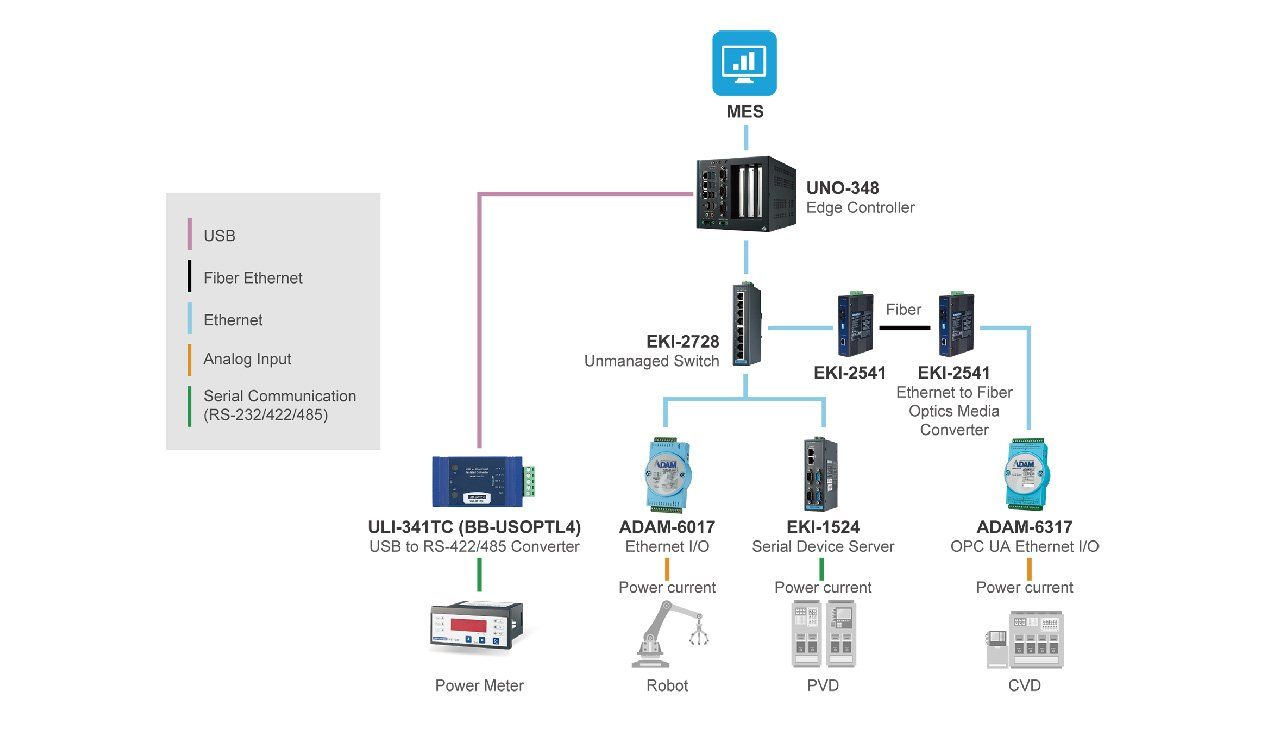

Success Stories & System Topologies

Products Offerings

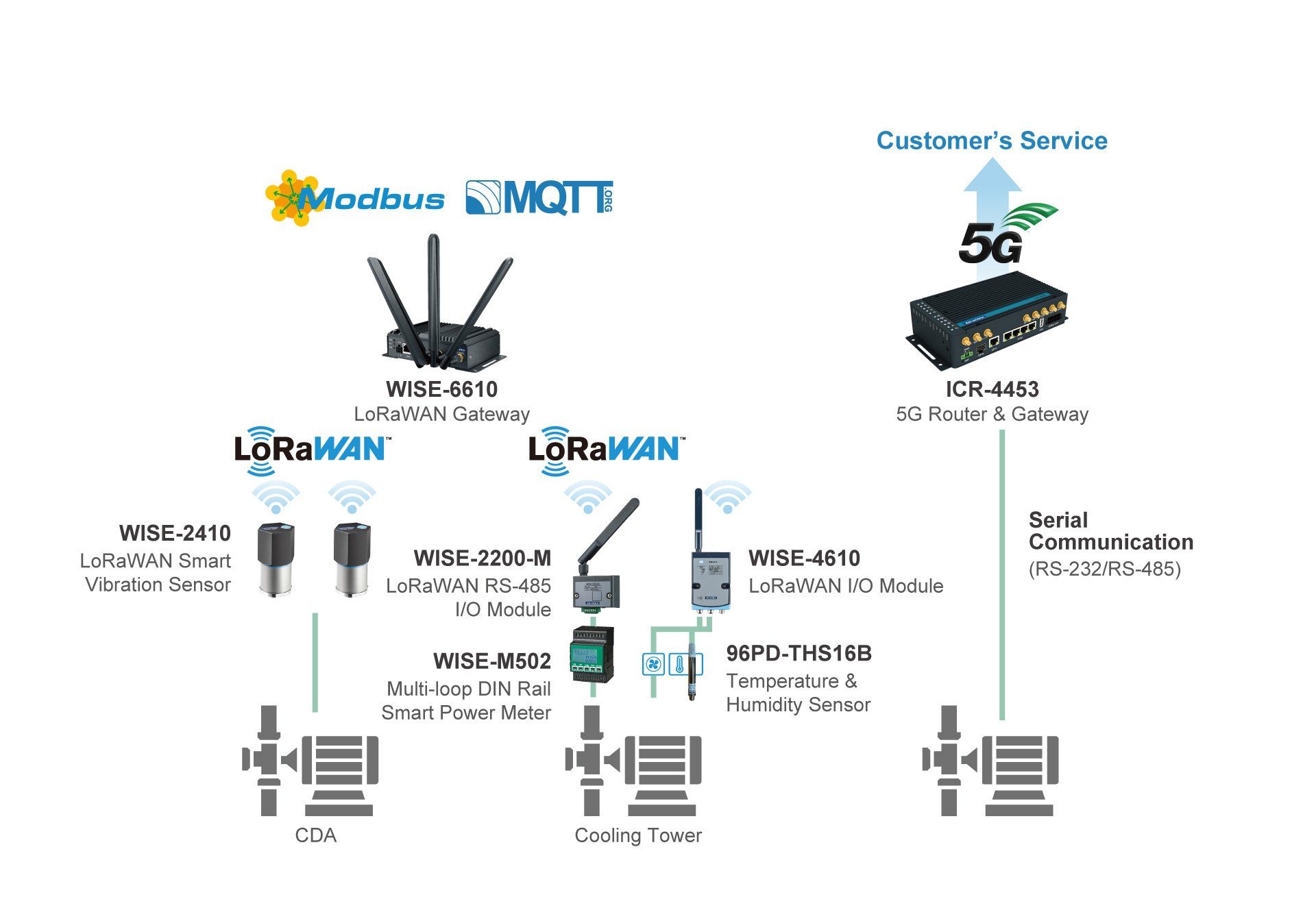

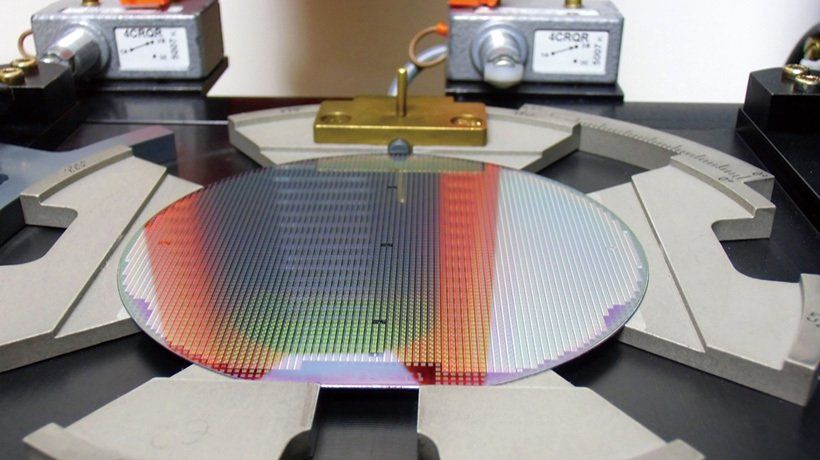

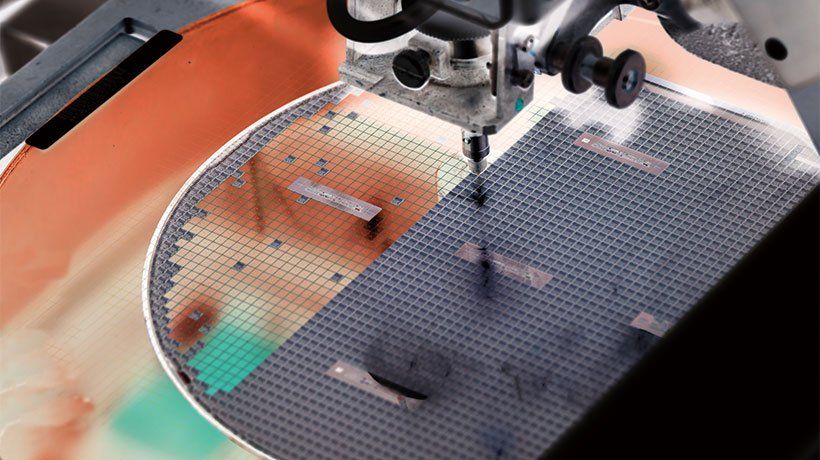

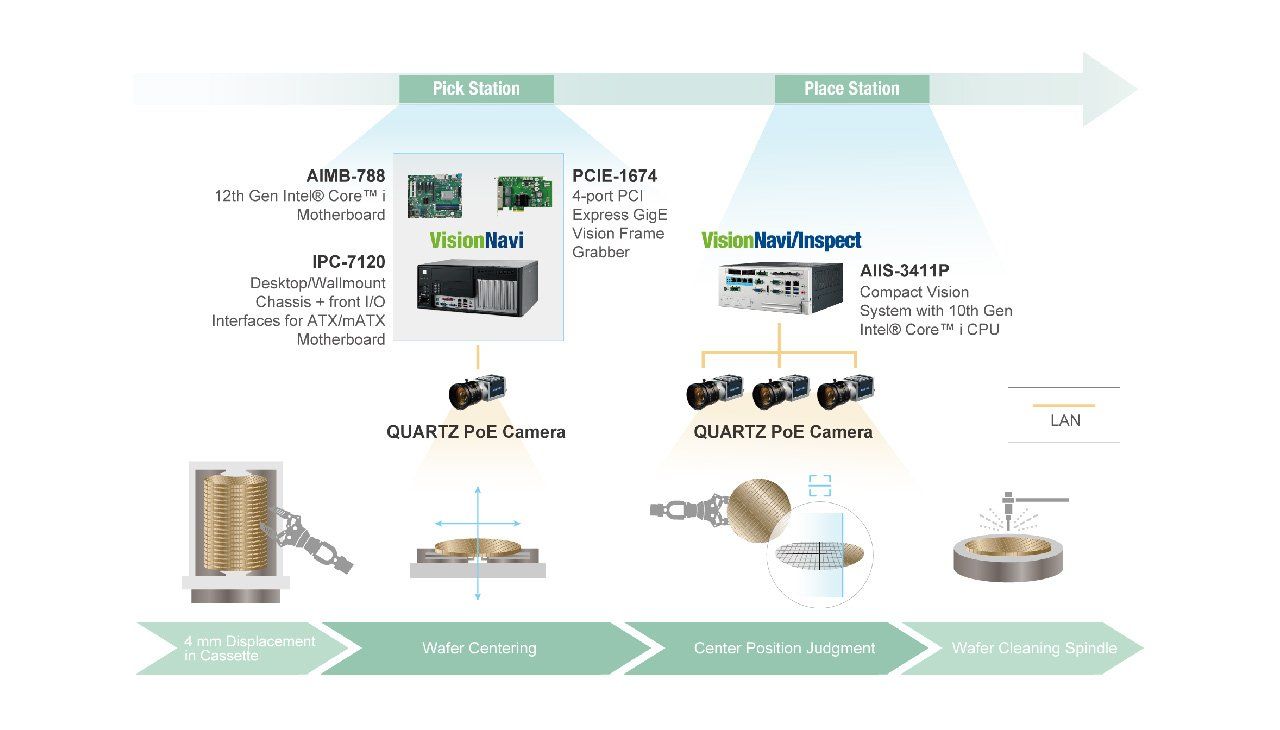

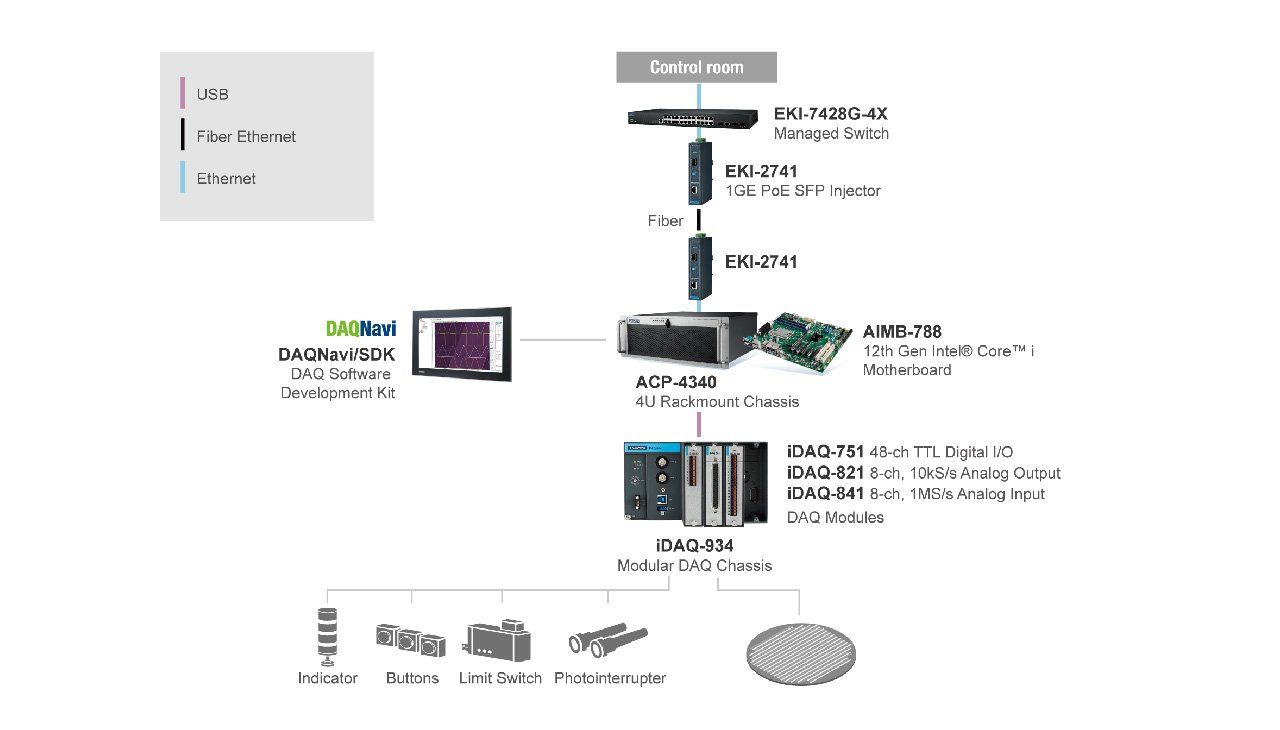

Semiconductor Remote Facility Management

Boosting Semiconductor Manufacturing Excellence

Application Scenario

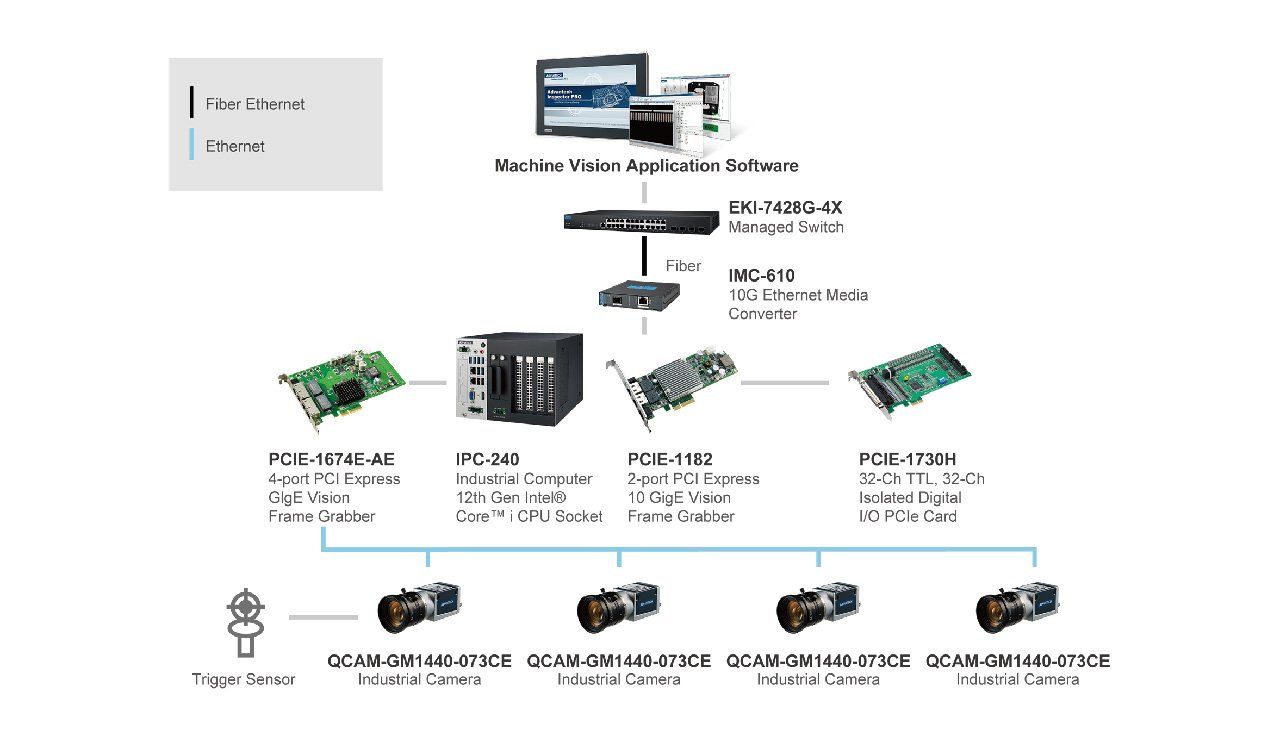

Success Stories & System Topologies

Product Offerings

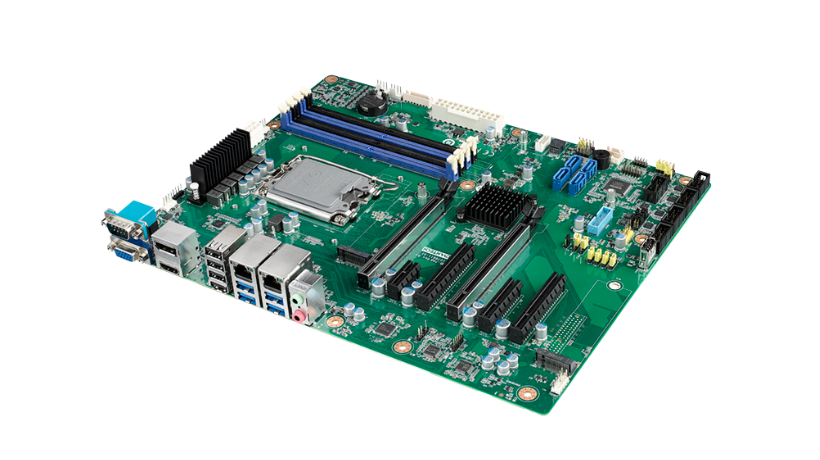

Industrial ATX Motherboard | LGA1700 12th Gen Intel® Core™ i9/i7/i5/i3 CPU

AIMB-788E

Renewable Energy Remote Facility Management

Improving Energy Effiecency

Application Senario

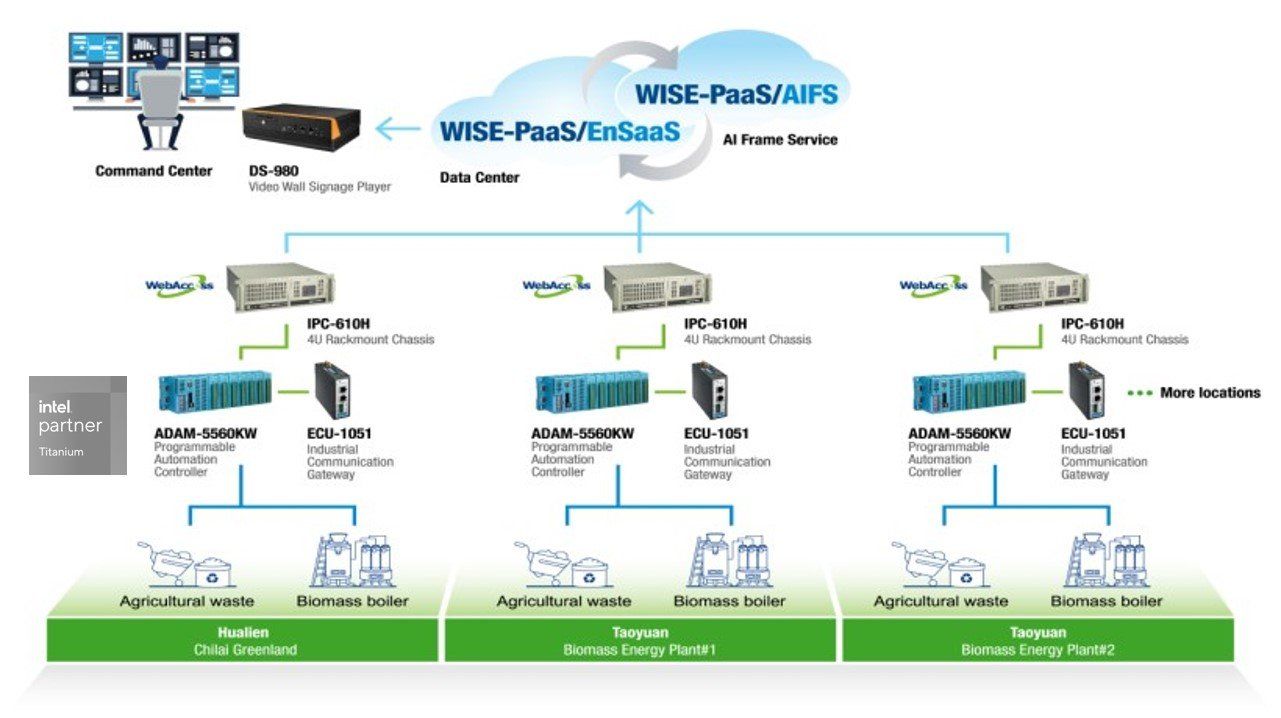

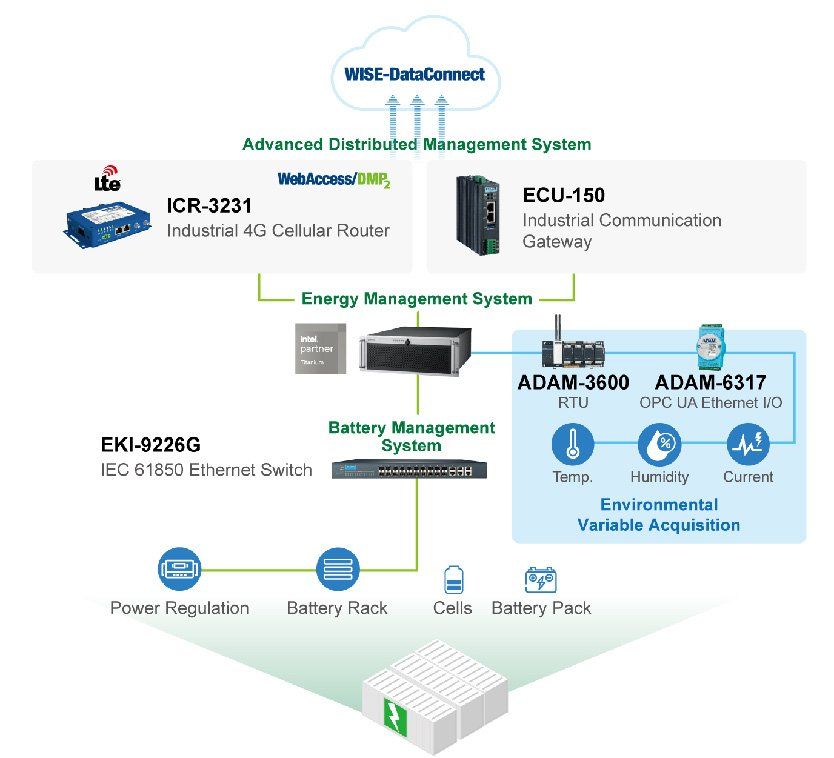

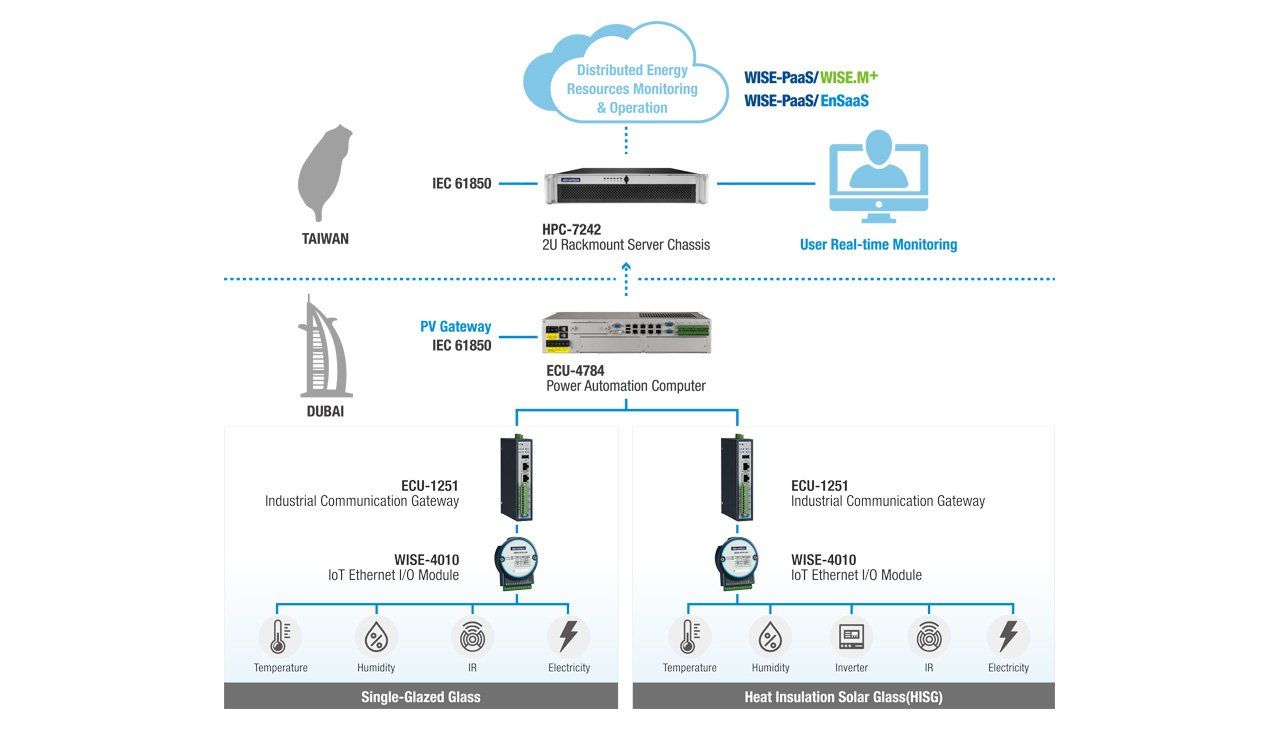

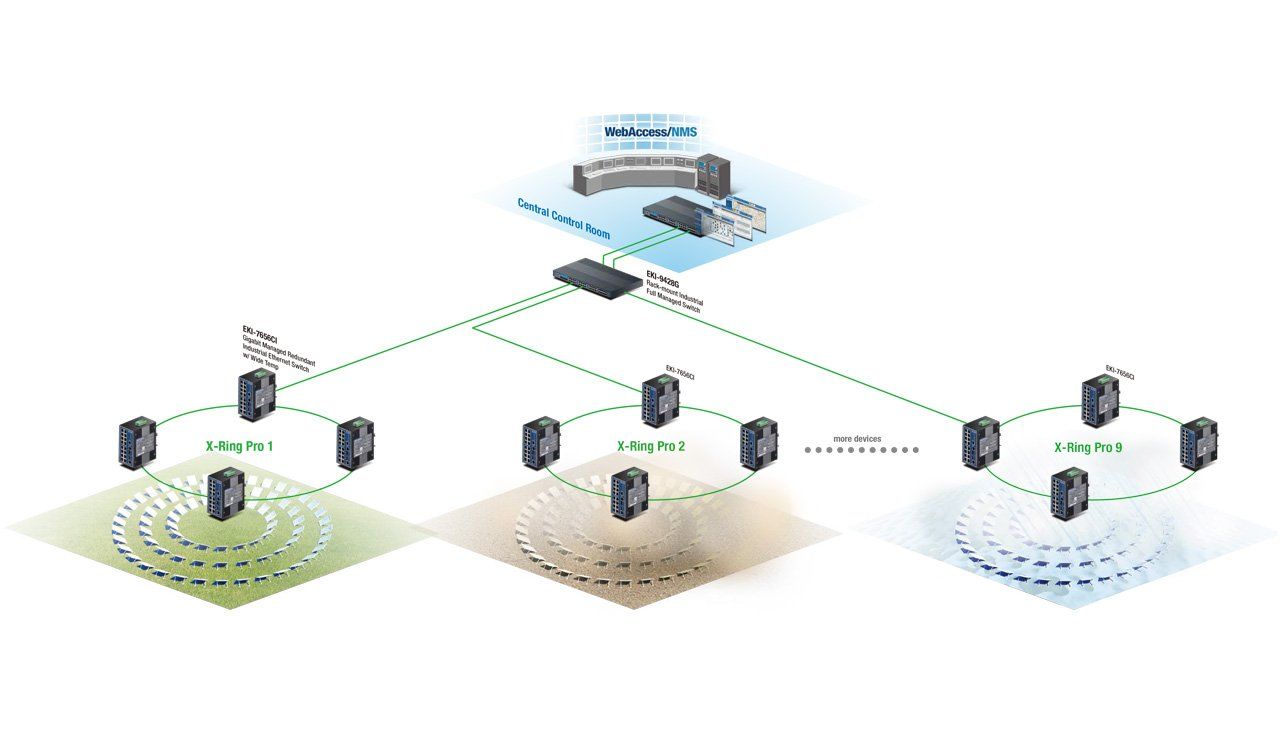

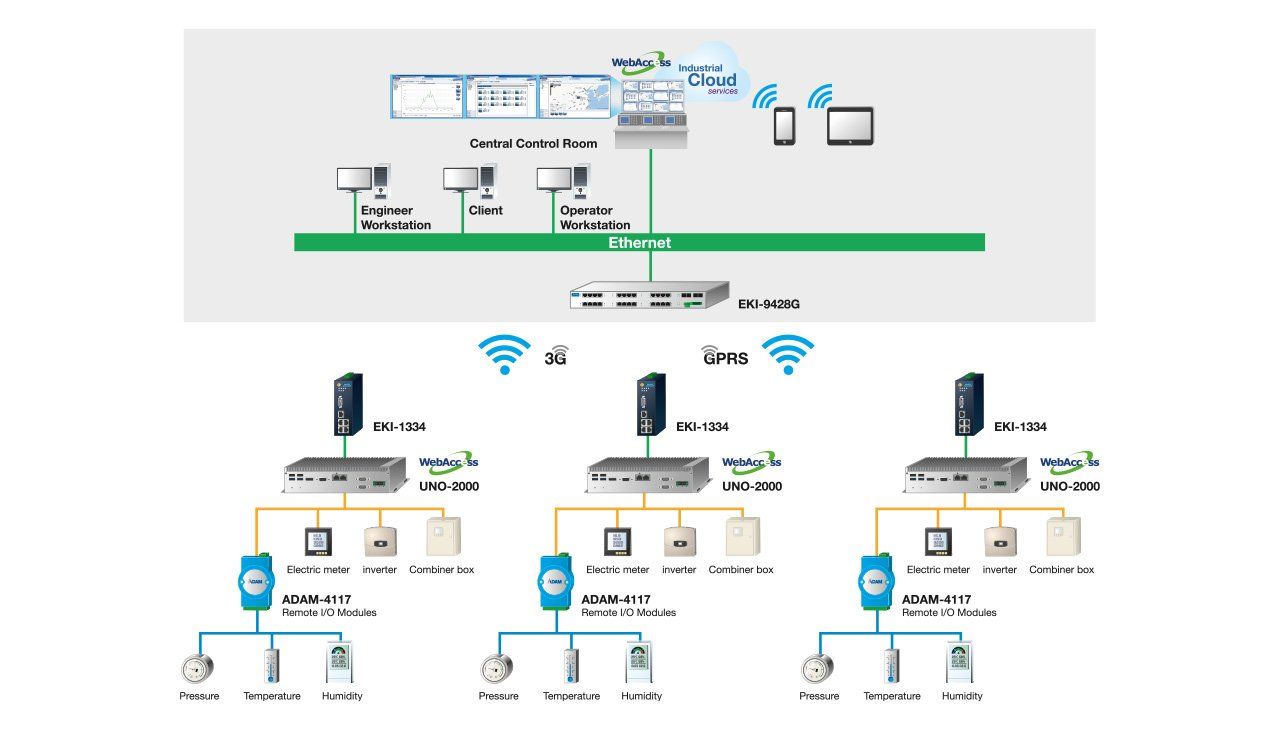

Success Stories & System Topologies

Product Offerings

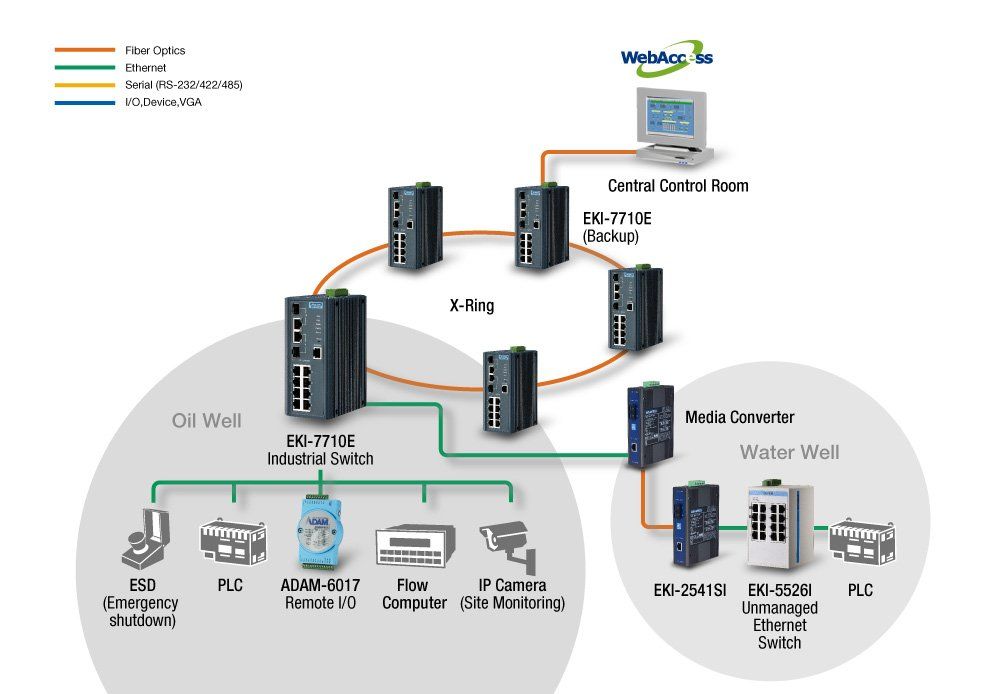

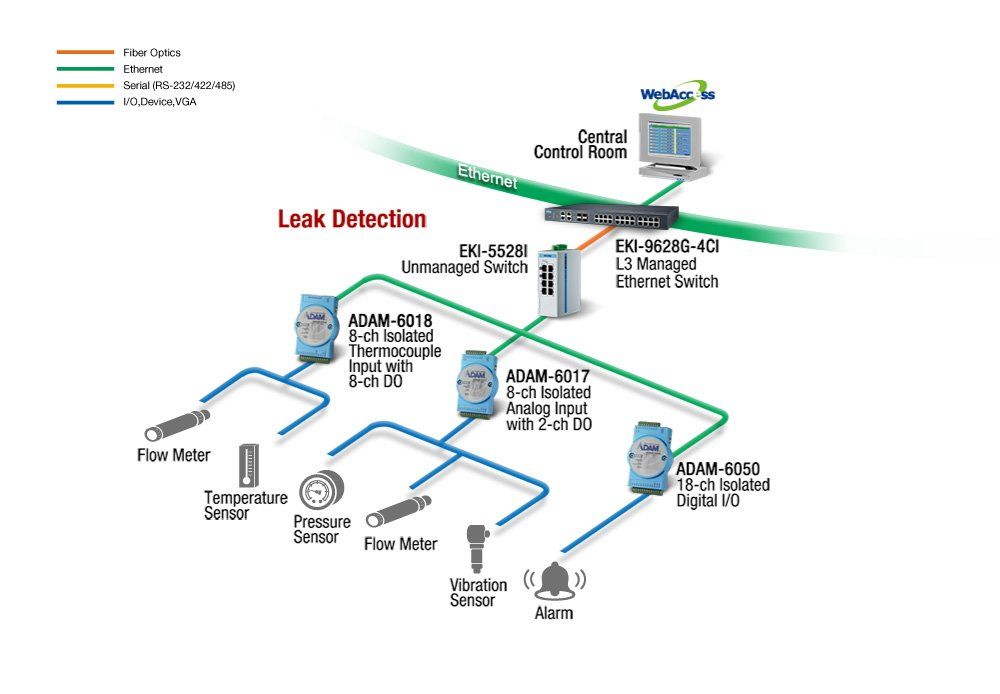

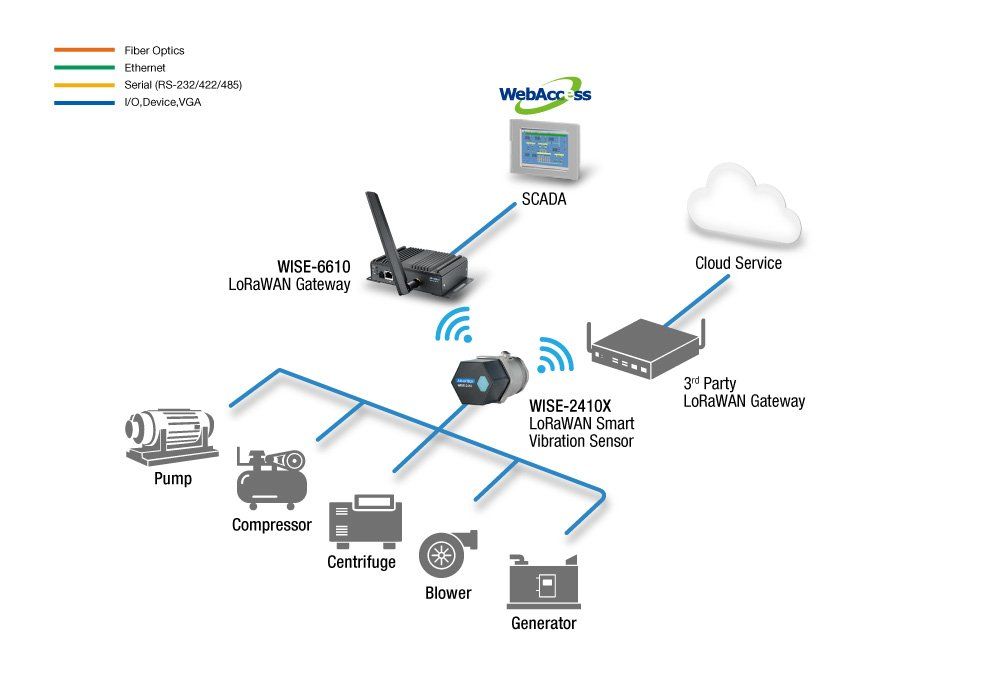

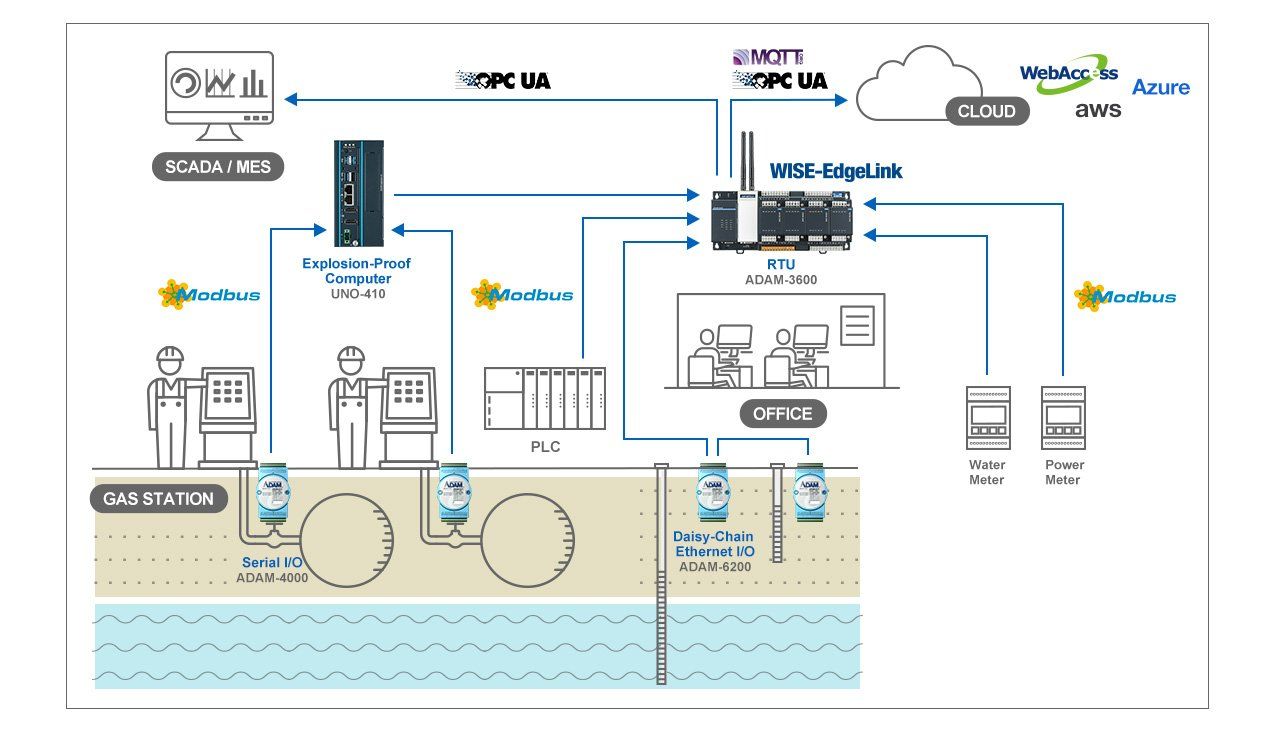

Oil & Gas Remote Facility Management

Empowering Mission-critical Applications

Application Scenario

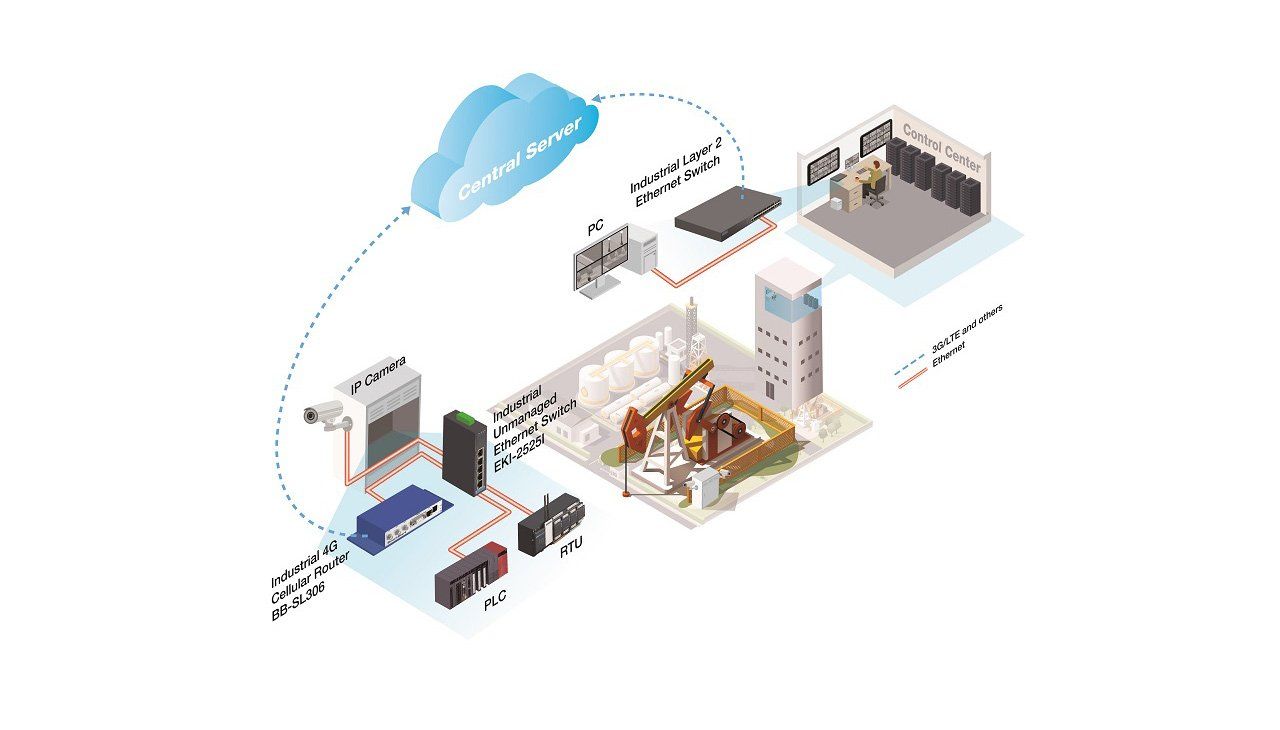

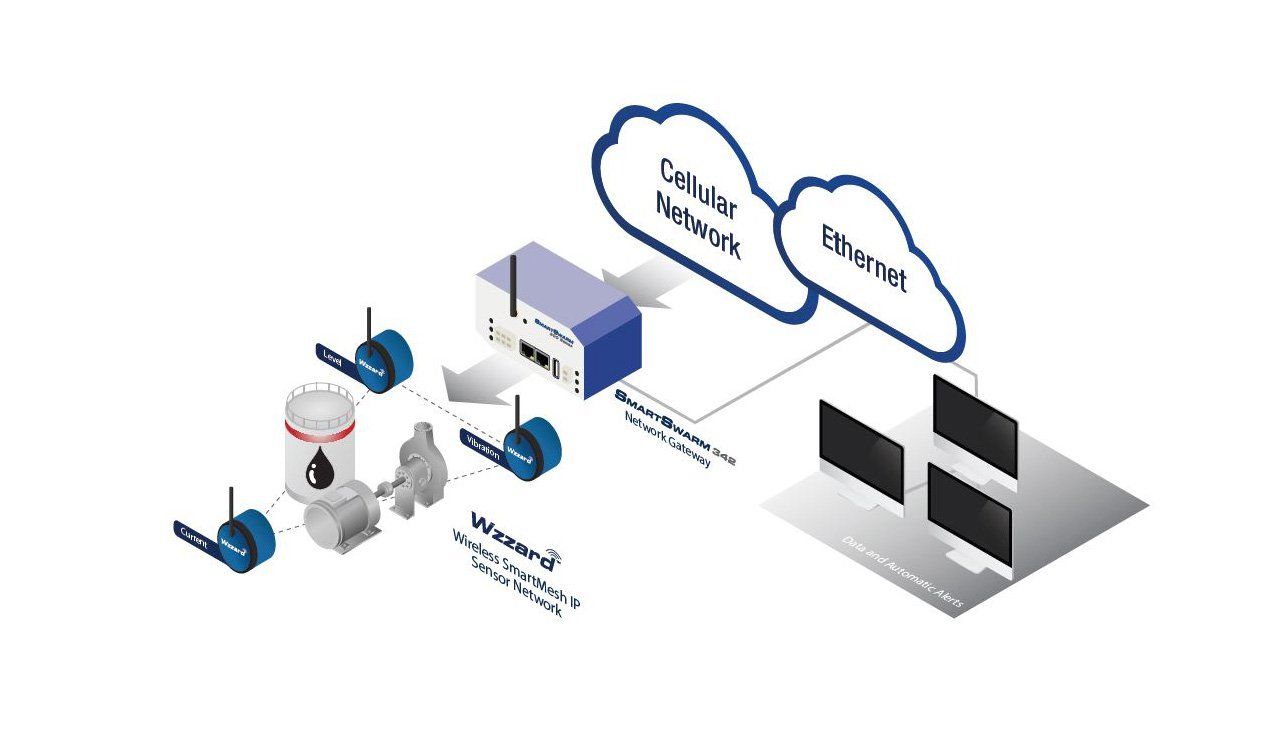

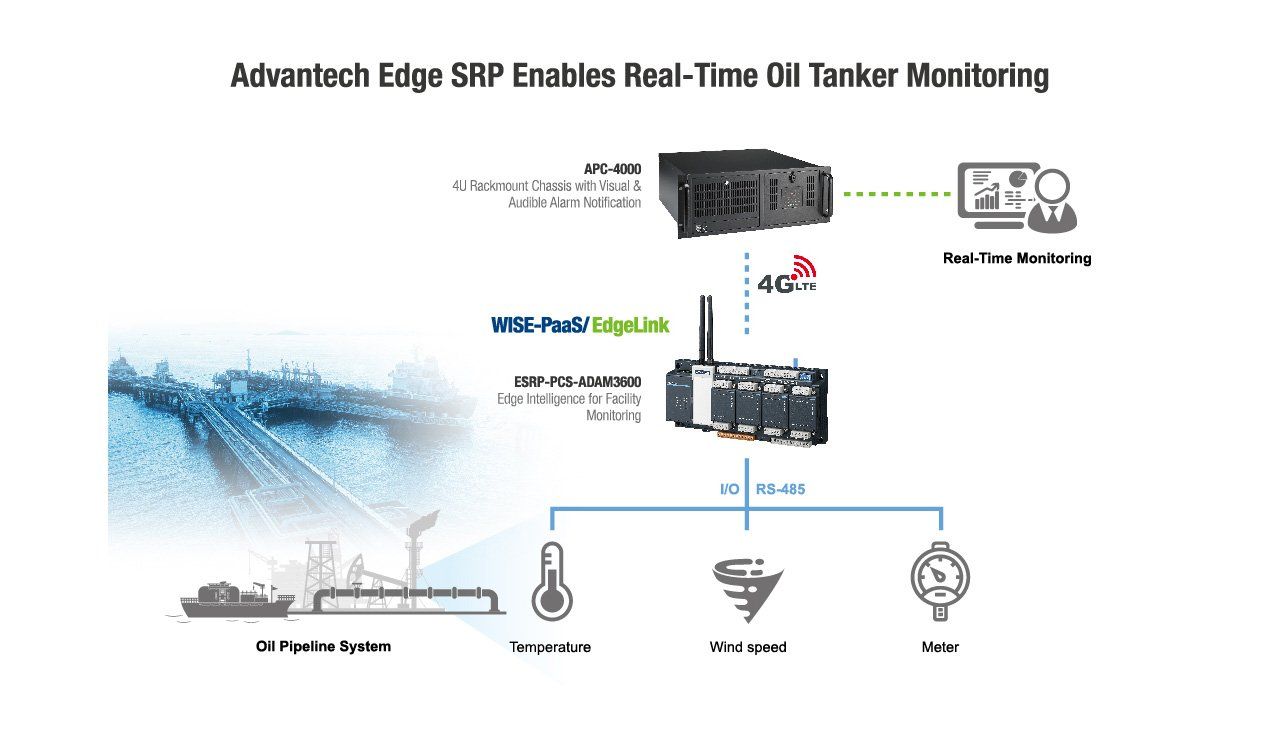

Success Stories & System Topologies

C1D2 Certified Product Offerings

Resources Download

Industrial IoT Systems and Automation Star Product Guide

Discover Advantech latest industrial IoT products and solutions covering:

- Vertical Marketing Solutions

- Edge AI Technology

- Edge Computing

- Automation Control

- Intelligent Connectivity

- Edge Data Acquisition

- Wireless Sensing and Fleet Networking

Industrial Equipment Manufacturing Success Cases

Find out how Advantech helped our customers achieve industrial equipment manufacturing success in different aspects.

- Electronic Manufacturing

- Semiconductor

- Food and Beverage

- Components

- Automated Guided Vehicle

- Test and Measurements

Industrial Communication & Networking

Providing interconnected solutions for enabling an intelligent planet:

- Industrail Ethernet Switches

- Industrial Gateway

- Industrial Cellular Router

- Industrial Wireless Solution

- Industrial Media Converter

- Serial / USB Communication

Advantech Newsletter