Join us on Food Technology Event

Register for FREE tickets

Join us next week for Food Technology event in den Bosch 🇳🇱, where you can find out about how together with our partner Captic we can co-create the future of food processing!

- Date: 12-13 April 2023

- Location: Brabanthallen, den Bosch, the Netherlands

- Free ticket and further information: https://food-technology.nl/register

“Efficiency, Effectiveness and Safety”

Keywords for the Food and Beverage Market

Producers in the Food & Beverage market expect to take advantage of the power of automation to carry out hazardous, repetitive tasks precisely and accurately, and to change the product rapidly in line with market forces, as well as supporting the strict health and trade legislation

The latest technologies of IoT, AI/ML, GPU, SDN, 5G, MPN, are now available to help improve OEE and ROI, and for those who don’t understand the acronyms, Advantech is here to help.

Advantech leverages new automation and AI technology to give manufacturers higher flexibility in production and management efficiency

with rugged Industry 4.0 solutions offering flexible and efficient ways for food & beverage manufacturers to fulfill high demands in product variability while maintaining the safety of the food and supply.

"There is no business or industry that can’t benefit from visualizing their data,

but manufacturers are the one group that can’t survive without it.”

– Peter Begle Business Online

Automation

Increasing automation in the food and drink industry usually means the collection of machine and batch production data, raising it in real time to managers of maintenance and production, and displaying results in the work area. Working alongside traditional control systems, these data streams facilitate the optimization of internal processes, increase machine utilization and productivity, and achieve improved energy efficiency.

Requirements:

- Small, robust devices, gateways or edge computers to physically connect to machines or PLC's to collect the data.

- Protocol convertors (software or hardware) to convert the machine data into readable format, such as OPC UA

- Local and Wide area communication equipment to send data to the Cloud, or local server for use

- Andon displays, located visibly near work stations

Advantech Highlights

We provide a wide range of data acquisition, protocol conversion, edge processing and onward transmission products that can connect almost any factory machine to any IT application. These are industrial products with the longevity, robustness and features needed for the demanding environment of a modern food or drink plant.

Quality Control

Food quality using human visual inspection is liable to fluctuations due to changing staff, inattention, distractions and fatigue. The introduction of artificial intelligence and machine learning to aid inspection, training automated systems with the best performing human visual inspectors at the peak of their efficiency, can significantly improve inspection accuracy. This permits an increase in production speed and overall effectiveness and efficiency.

Requirements:

- AI-enabled cameras, or analogue/digital cameras with

- Small and robust edge computers with

- AI-enabled GPUs or vision-capable CPUS

Advantech Highlights

Advantech has the world’s largest range of industrial computers for AI/ML and computer vision applications, from powerful servers capable of deep learning the most complex production problem, through tiny edge computers with powerful graphic processors for visual inspection video streams, to AI-enabled cameras.

Food Traceability

Food production requires total food history management systems that can record data and track workflows, which improves food quality and safety while boosting uptime and reducing maintenance cost

Requirements:

- Secure, reliable IT/OT connectivity

- Data Visualisation

- Remote Management

Case Studies

Advantech works globally across many Food and Beverage industries - including machine builders that supply specialist equipment to F&B alongside the factories themselves. Below you will find a few examples of our projects covering a variety of our area's of expertise. We would be delighted to learn more about your challenges and how we can support you from a technology perspective.

Automatic Vision Inspection Solution for Product Traceability in the Food and Beverage Industry

One of the world's leading providers of beverage containers required a system to identify bar codes and alphanumeric characters on ink-jet-printed labels with a minimum 99.9% accuracy.

Advantech provided a PC-based automated optical identification (AOI) system with multiple cameras to identify bar codes, data codes, and characters on the beverage containers. Multiple cameras were connected to each AIIS computer, with the results of the inspection escalated to the control room server and display.

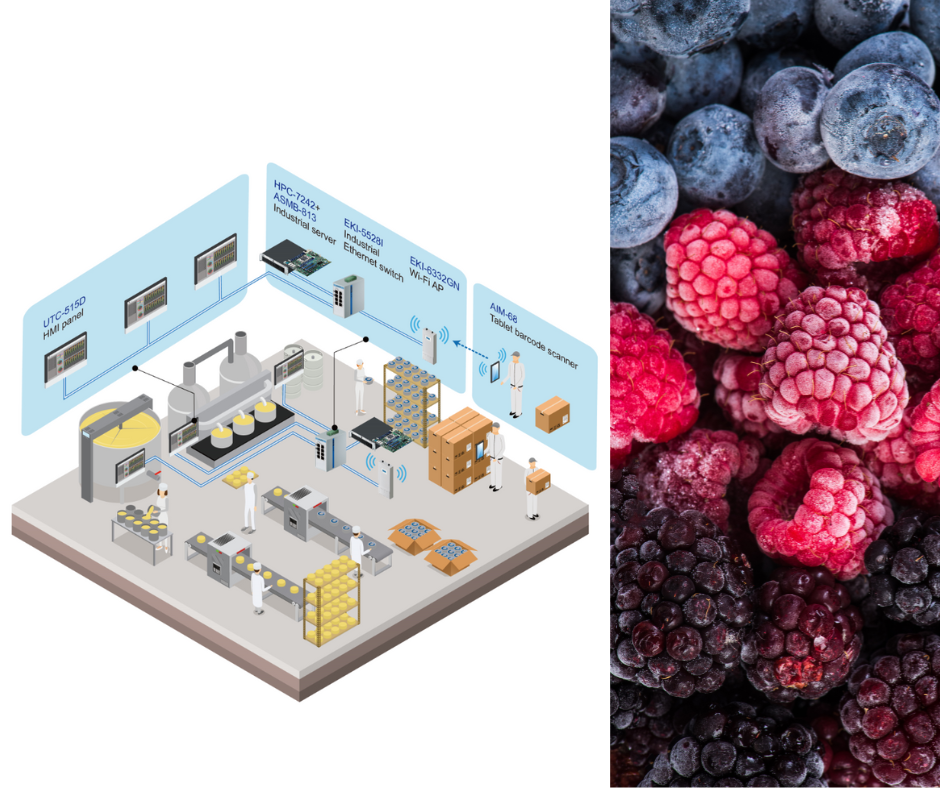

Frozen Foods Manufacturing Execution System (MES)

Extremes of temperature and humidity are common on food and drink production, especially where chilled drinks or frozen foods. Such conditions, especially where production or logistics processes involve rapid changes from the heat of production to the cold of storage, are especially harsh on the automation and electronic equipment that controls or monitors the process

Devices such as touch computers and handheld or mobile devices and scanners are especially susceptible. Employee training and personal safety equipment such as gloves also affect the use of these devices. Advantech cooperated with a system integrator to provide a complete range of devices for a cold chain operator looking for a new MES system. With an operating temperature range from -40°C up to 75°C, Advantech’s wide product portfolio is ideal.

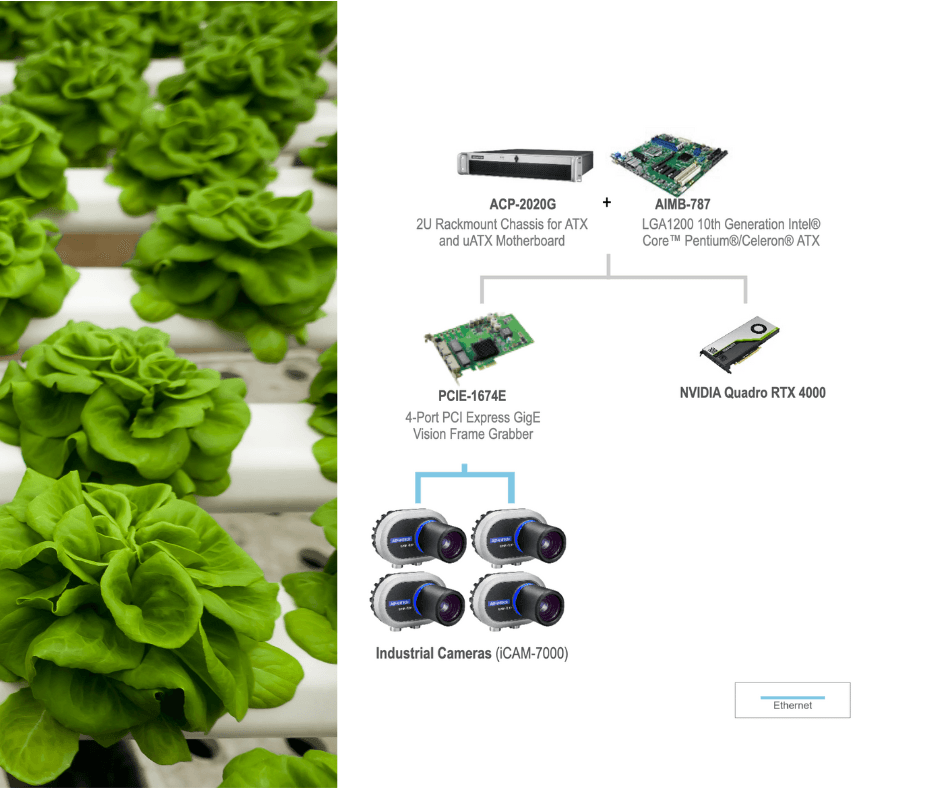

AI AOI Empowered Intelligent Fruit Sorting

In traditional fruit production, the sorting and grading of fruit relied on experienced

personnel to classify fruits according to their quality. However, with the aging of the rural population and now COVID, farmers and distributors are facing labor shortages. Although general fruit sorting machines can reduce labor requirements, production still needs human assistance.

An apple sorting solution was applied using automated optical inspection supported by Advantech ACP-2020G with 2U rackmount chassis design and AIMB-787 motherboard. This enabled the sorting system to collect the images from visual inspections by cameras, and with an NVIDIA RTX 4000 GPU card support, analyzed and recognized the apples' weight, color, surface defects and more, to reduce labor requirements, increase the quality and brand value of fruit production, and provide unparalleled sorting consistency and accuracy, to help agriculture businesses face an increasingly competitive agricultural environment.

Download Articles - Dedicated to Food & Beverage

Advantech Products & Services

Rugged Industrial Displays

Advantech’s industrial display solutions, which include Panel PCs and a stainless steel waterproof monitor, are specifically designed for the food and beverage industry. All components are easy to clean and disinfect. In addition, they are corrosion resistant which helps to prevent cross-contamination

Visualising Operations

Advantech provides a series of real-time control and data analysis solutions that are capable of summarizing the results of multiple processes and visually showing the performance/efficiency of each task in real time on a dashboard. This enables managers to make data driven decisions based on real-time data analysis.

Vision Inspection

Advantech's machine vision systems are renowned for their high performance, large number of I/O ports, and flexible expansion. Offering vision cards, graphic cards, and motion cards, Advantech’s machine vision systems are an ideal choice for vision inspection and traceability systems

Intelligent Connectivity

Advantech leverages over 35 years of industry experience in developing reliable wired and wireless communication solutions for mission critical applications, all of which contribute to securely transmitting data, and monitoring and controlling networked devices.

Follow Advantech